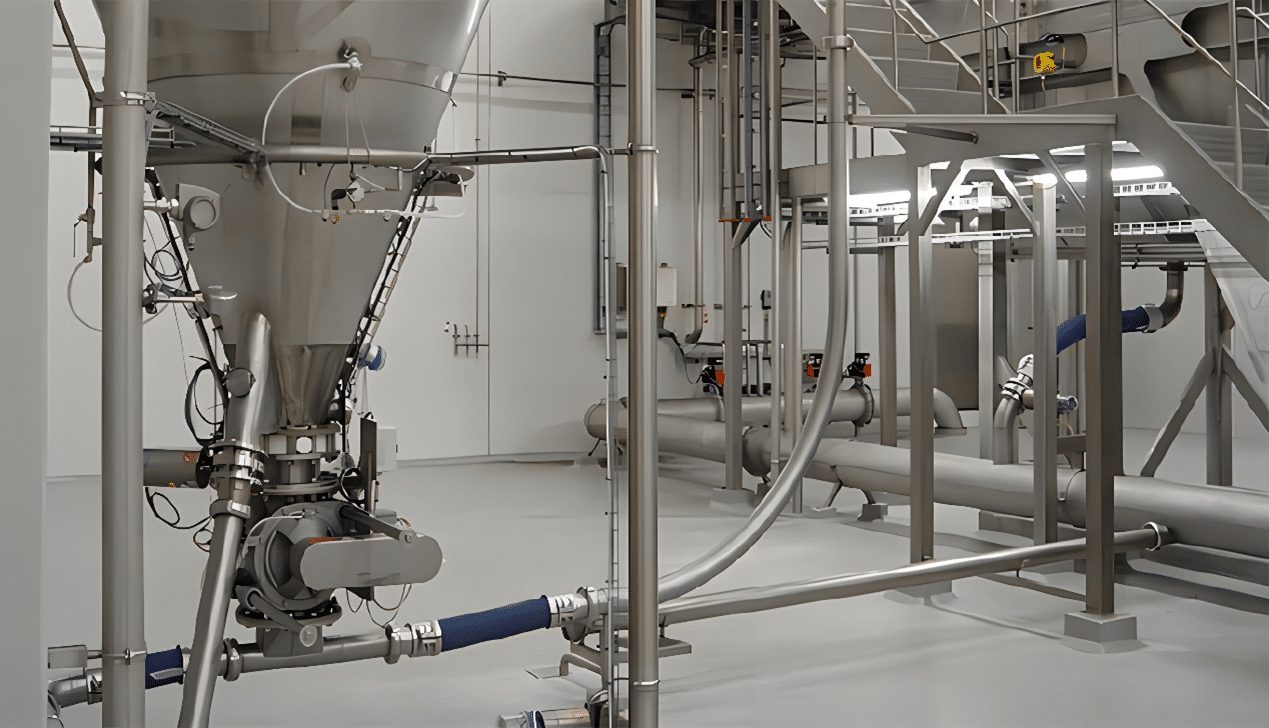

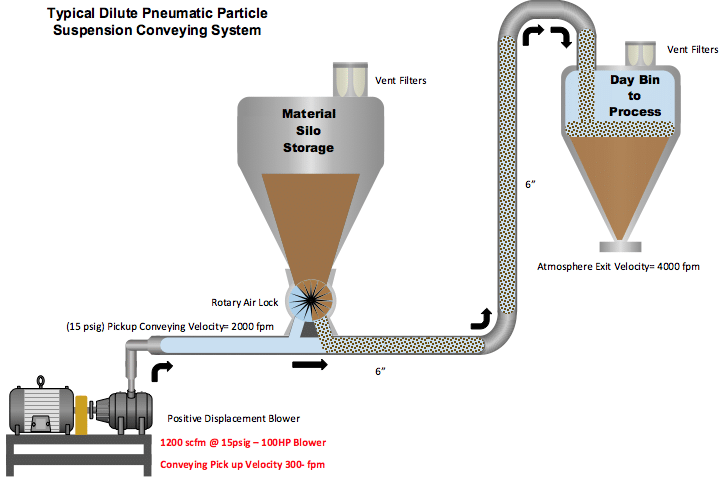

In dilute phase positive pressure conveying, the material to be transported is suspended in a high-velocity air stream, allowing it to flow easily through the conveying line. This method is ideal for handling materials that are free-flowing and non-abrasive. The positive pressure helps push the material along the pipeline, ensuring efficient and reliable transportation. By carefully controlling the air pressure and velocity, operators can prevent material degradation and ensure gentle handling throughout the conveying process. Dilute phase positive pressure conveying is a versatile and effective solution for industries requiring precise and controlled material transport.