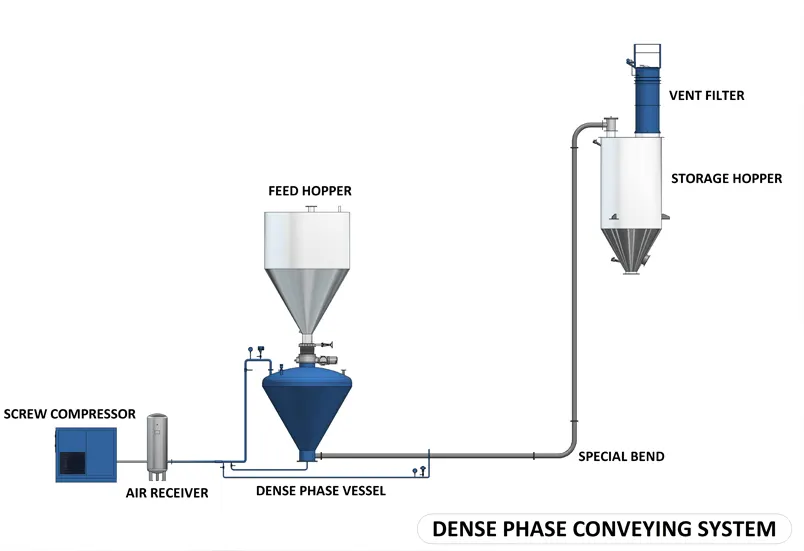

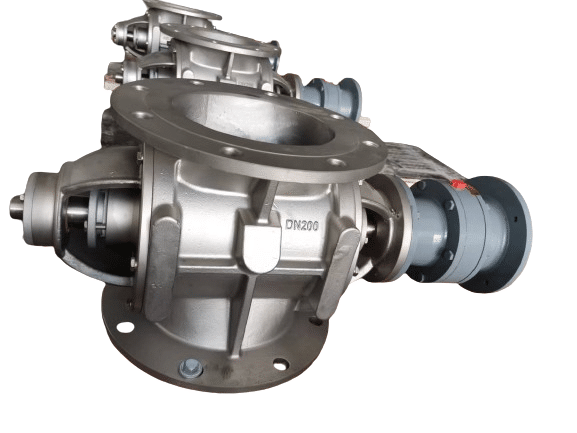

Energy Efficiency and Environmental Impact: Dense phase conveying systems distinguish themselves by operating at low energy consumption levels, establishing them as a cost-effective and environmentally friendly alternative compared to conventional conveying methods. This not only contributes to reduced operational costs but also aligns with sustainability goals.

Material Handling Expertise: Renowned for their gentle handling capabilities, dense phase conveying systems are adept at transporting fragile granular materials and powders with particle sizes below 2mm. Their controlled transportation process mitigates breakage or degradation during conveyance, ensuring the preservation of material integrity.

Longevity Through Reduced Wear: The controlled movement of materials in solid form within dense phase conveying systems leads to significantly reduced wear on pipes. This characteristic minimizes abrasion, extending the lifespan of the conveying system and contributing to long-term cost savings.

Efficient Dust Management: Dense phase conveying systems excel in dust removal, facilitated by their small conveying air volume and low energy consumption. This efficiency streamlines the separation and dust removal processes, fostering a cleaner and safer working environment.

Preservation of Material Integrity: By maintaining low velocities and stable conditions during transport, dense phase conveying systems prevent material degradation. This feature is particularly crucial for delicate materials, ensuring the preservation of their integrity throughout the transportation process.

Homogeneity in Material Blending: Dense phase conveying minimizes the segregation of blended materials by ensuring that different components are conveyed at similar velocities. This meticulous approach preserves the homogeneity of the mixture, maintaining consistency throughout transportation.

Optimized Maintenance Efficiency: Operating at low velocities, dense phase conveying systems experience minimal wear on pipelines, resulting in extended pipeline life and reduced maintenance requirements. This translates to lower downtime and overall maintenance costs, enhancing operational efficiency.

Compact Ancillary Equipment: The low air consumption of dense phase conveying systems allows for the utilization of smaller filters, compressors, and dryers. This not only reduces initial installation costs but also leads to decreased maintenance expenses, contributing to overall system cost-effectiveness.