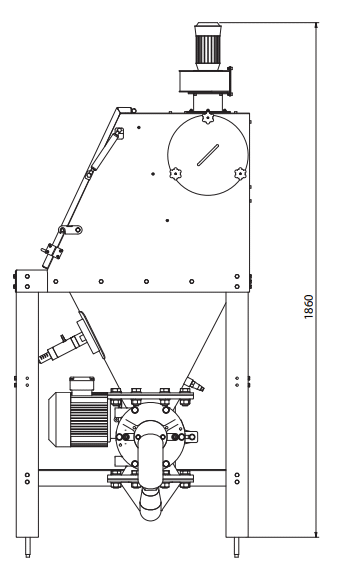

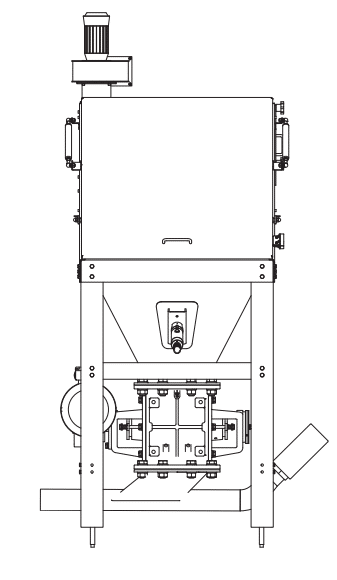

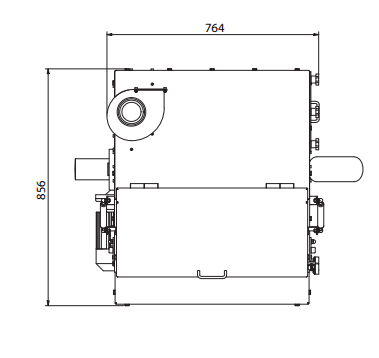

The Bag Dump Station is a pivotal component in material handling systems, providing a controlled environment for the efficient transfer of bulk materials from bags into downstream processes. Designed with user convenience in mind, the station features a sturdy work surface and an integrated dust collection system to maintain a clean and safe working environment. Its ergonomic design facilitates manual bag handling, allowing operators to easily empty bags into the station