This guide delves into common powder transport methods and the key considerations for choosing the most suitable option for your needs.

Common Powder Transport Techniques

- Pneumatic Conveying: This method utilizes compressed air to propel powders through a pipeline, offering:

- Adaptability: Well-suited for intricate layouts with bends and inclines.

- Enclosed System: Minimizes dust generation.

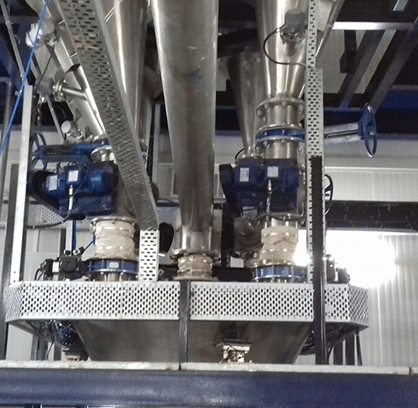

- Vacuum Conveying: In this method, a vacuum pump creates suction to move powders, providing:

- Delicate Material Handling: Ideal for fragile or abrasive materials.

- Dust-Free Operation: Ensures a clean work environment.

- Belt Conveying: This method employs a belt to continuously transport powders, offering:

- Cost-Efficiency: Often the most economical option for short distances.

- High Capacity: Suitable for large-volume powder movement.

- Bucket Elevator: This method utilizes buckets attached to a belt or chain to vertically elevate powders, providing:

- Vertical Transportation: Ideal for lifting powders to different levels.

- Controlled Flow: Enables precise material metering.

Choosing the Right Method

Several factors influence the selection of the most appropriate method:

- Conveying Distance: Shorter distances may favor screw conveyors for their simplicity and cost-effectiveness. Longer distances often benefit from pneumatic or vacuum conveying for their flexibility.

- Pipeline Direction: Complex layouts with numerous bends might favor pneumatic or vacuum conveying due to their simpler pipe routing.

- Material Characteristics: Delicate or abrasive materials might necessitate the gentler handling offered by vacuum conveying.

- Efficiency Requirements: High-volume and automated processes might favor pneumatic conveying for its efficiency.

Additional Considerations

- Visual Appeal: Consider the aesthetic impact of the chosen method on your facility’s layout.

- Expert Advice: Consult a qualified powder handling specialist to ensure optimal system design and operation.

Shanghai Youwei: Your Partner in Powder Handling Solutions

Shanghai Youwei boasts extensive experience in designing powder conveying solutions for various industries, including lithium battery, food, and chemical sectors. We offer:

- Custom-Tailored Solutions: We design systems to your specific needs and site conditions.

- Proven Designs, Reliable Performance: Our well-established designs ensure reliable and efficient powder transport.

Contact Us Today

For a comprehensive consultation on selecting the ideal powder transport method for your application, contact Shanghai Youwei today!