The production of carbon nanotube conductive slurry, a rising star in lithium battery technology, requires precise metering of carbon nanotube powder and dispersants. Manual feeding becomes a bottleneck for companies seeking to scale production while maintaining quality. This article explores how to achieve dust-free, automatic feeding for this process, optimizing efficiency and consistency.

Why Automate Carbon Nanotube Conductive Slurry Feeding?

Traditional manual feeding methods hinder production capabilities and quality control:

- Limited Throughput: Manual feeding struggles to keep pace with expanding production demands.

- Inconsistent Accuracy: Manual weighing inconsistencies lead to production quality issues and material waste.

- Unhealthy Work Environment: Dust exposure creates safety hazards and a negative work environment.

- Hinders Growth: Manual processes can’t meet the quality standards required by large clients.

Automatic Feeding: The Solution

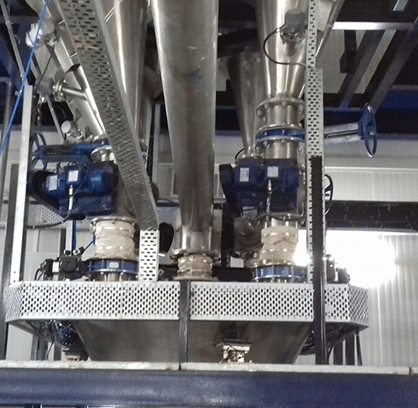

Shanghai Youwei Mechanical and Electrical Co., Ltd. offers an automated weighing and feeding system specifically designed for carbon nanotubes and dispersants. This system addresses the limitations of manual feeding and delivers:

- Increased Efficiency: Automates the weighing and feeding process, significantly boosting production output.

- Enhanced Accuracy: Integrates high-precision Mettler Toledo load cells for consistent material metering.

- Improved Work Environment: Closed feeding systems minimize dust exposure, promoting worker safety and a cleaner workspace.

- Higher Quality Standards: Ensures consistent material ratios for reliable, high-quality slurry production.

System Highlights

- Capacity: Handles dispersant feeding (3-10KG) and carbon nanotube feeding (20-50KG).

- Versatility: Accommodates up to four types of automatic weighing ingredients.

- Accuracy: Maintains weighing accuracy through a specially designed conveying system.

- Dust-Free Operation: Closed feeding process minimizes dust spillage.

- PLC + Touch Screen Control: Ensures user-friendly operation and system monitoring.

Proven Performance

Youwei’s system boasts a successful track record in the automated feeding of carbon nanotube conductive slurry. With its stable and reliable operation, this system empowers manufacturers to:

- Achieve production growth targets.

- Deliver superior product quality.

- Maintain a safe and healthy working environment.

Contact Youwei Today

Take your carbon nanotube conductive slurry production to the next level with Youwei’s automated feeding system. Contact Shanghai Youwei Powder Equipments CO.LTD today to discuss your specific requirements and learn how this innovative solution can optimize your production process.