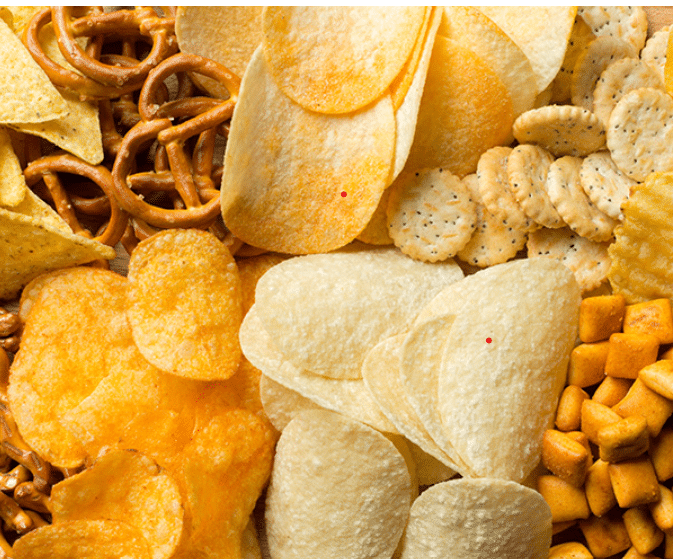

Weighing silos, also known as powder weighing hoppers or powder tanks, are specialized storage containers equipped with weighing sensors to accurately measure the weight of powder materials they contain. These silos are integral to various industries where precise powder measurement is crucial for process control, inventory management, and maintaining product quality.