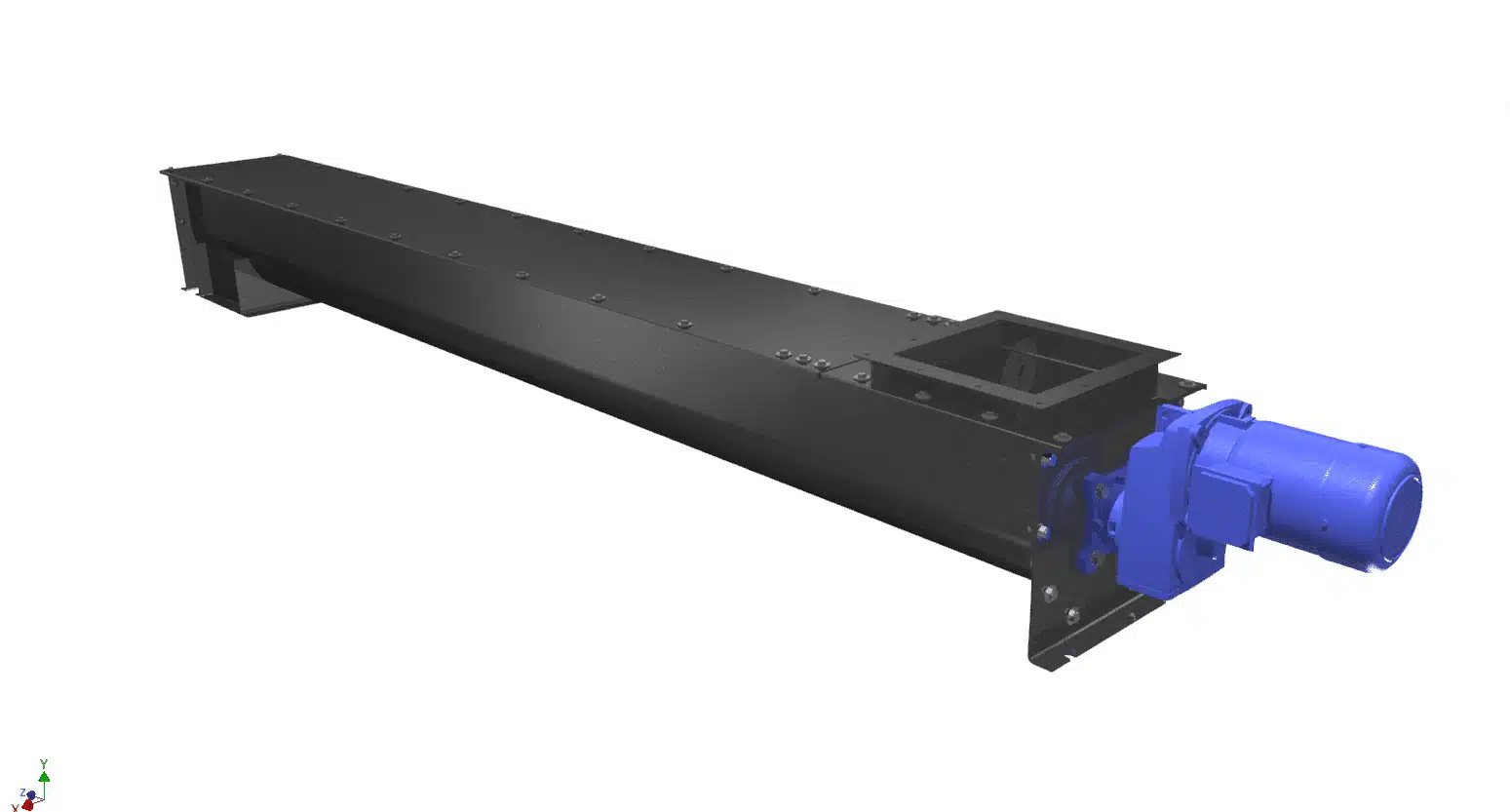

The UV-LX Trough Screw Conveyor system, known for its modular design, presents a range of solutions for the conveyance or feeding of powdery and granular materials. Specifically crafted for applications in the food industry and environmental technology, these conveyors excel in situations where avoiding material contamination is paramount, demanding absolute cleanliness and corrosion resistance. Widely applied in flour and animal feed milling, plastics, chemicals, and the pharmaceutical industry, the LX Trough Screw Conveyors showcase versatility across various sectors.