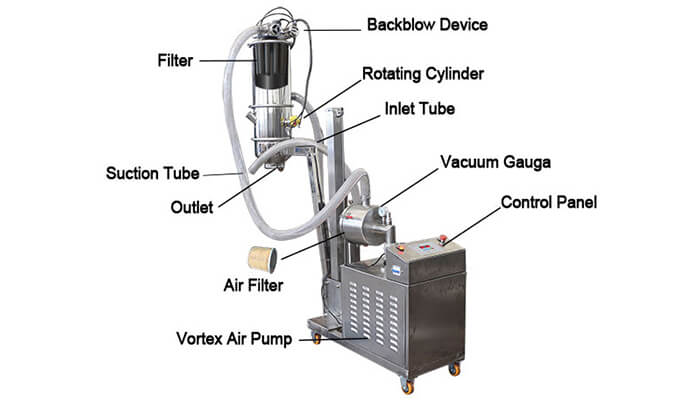

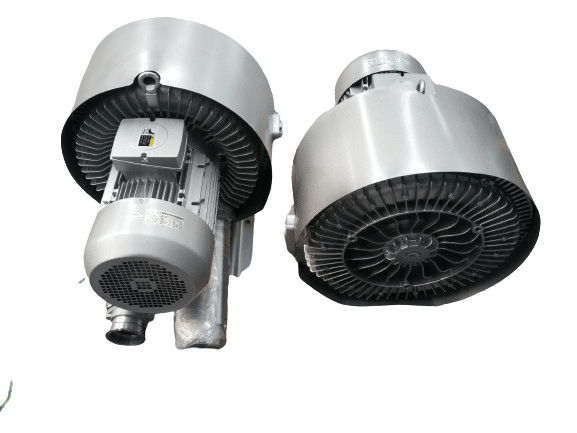

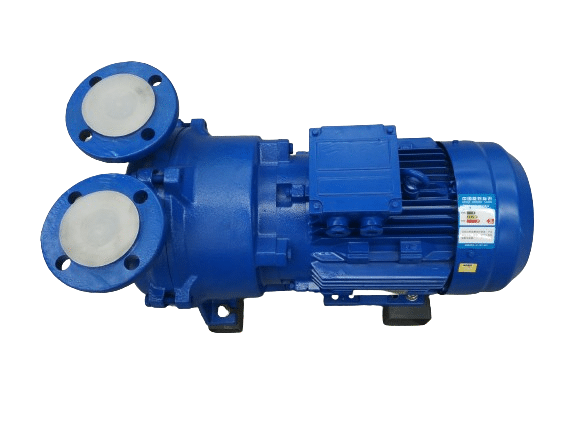

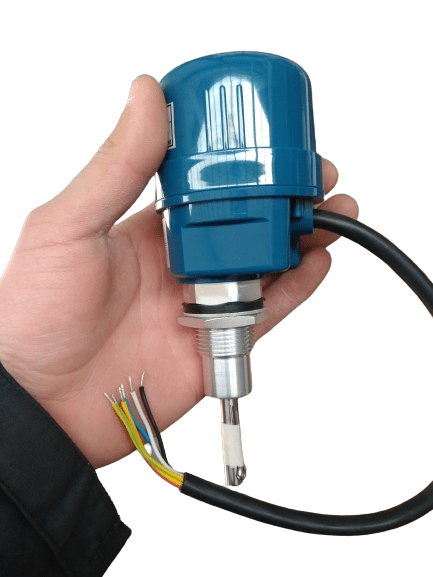

The Movable Vacuum Feeder, also known as Negative Pressure Conveying System, is a versatile and efficient solution for transporting powders, granules, and other materials in various industrial settings. This mobile system utilizes negative pressure to convey materials through pipelines, offering flexibility and ease of movement within production facilities. With its compact design and maneuverability, the Movable Vacuum Feeder provides a convenient and reliable method for material handling, contributing to enhanced productivity and streamlined operations.