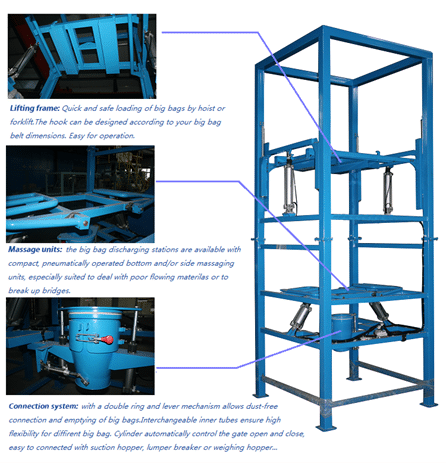

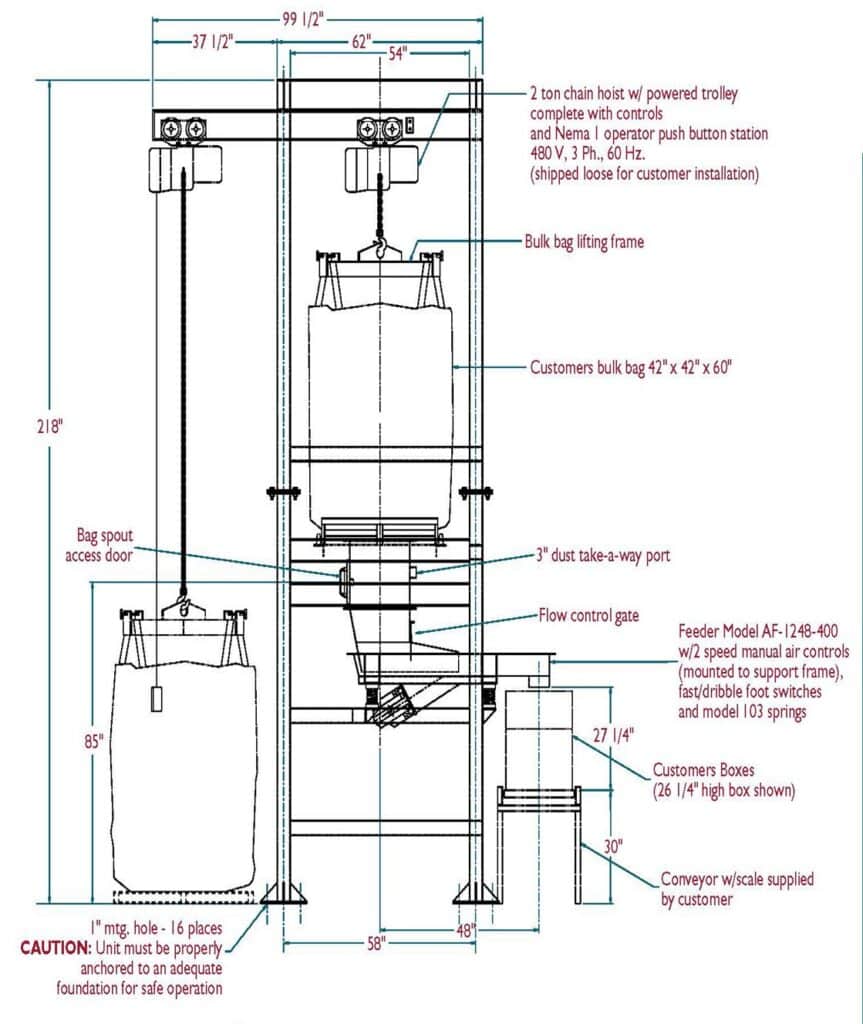

The Ton Bag Unloading Station simplifies the controlled discharge of bulk materials from Flexible Intermediate Bulk Containers (FIBCs). With a focus on efficiency and safety, this station features a stable structure, dust containment, and customizable options, offering a reliable solution for streamlined material handling across diverse industries.