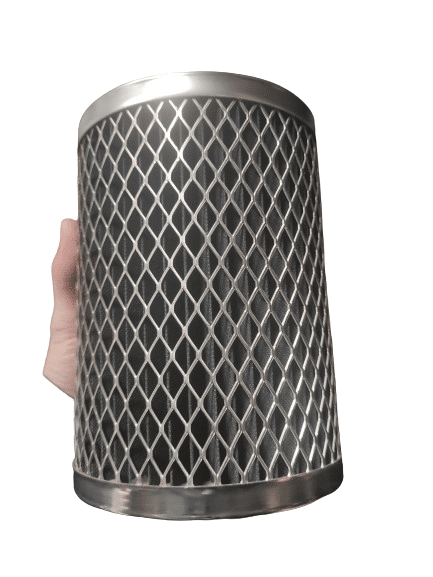

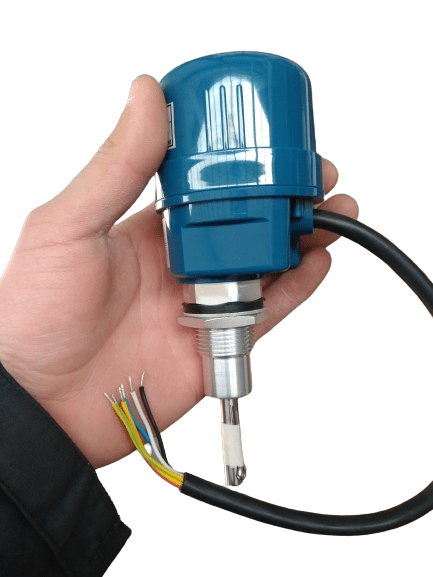

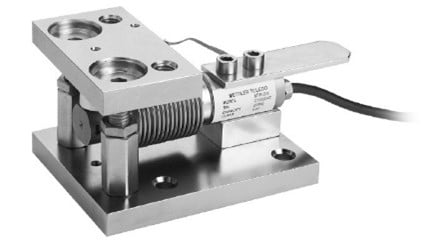

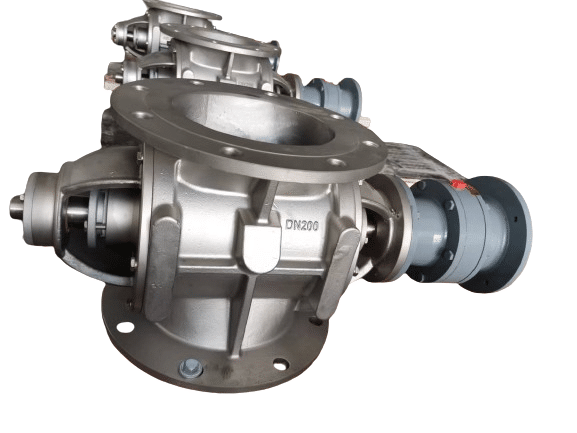

Shanghai Youwei Powder Equipment CO. LTD. is a leading manufacturer and supplier of storage silos for powder conveying systems. We have over 20 years of experience in designing, producing, and installing high-quality storage silos for various applications. Our storage silos are made of stainless steel 304/316L, with a large arc and no excessive dead ends. They comply with the standards of the food and drug industry and can be customized according to your specific requirements. Our storage silos can be equipped with various auxiliary components such as vibrators, unloading valves, load cells, breathing valves, material level switches, and more. Our storage silos are suitable for storing and conveying a wide range of powder and granular materials, such as flour, sugar, salt, starch, milk powder, coffee, cocoa, spices, pharmaceuticals, chemicals, and more.