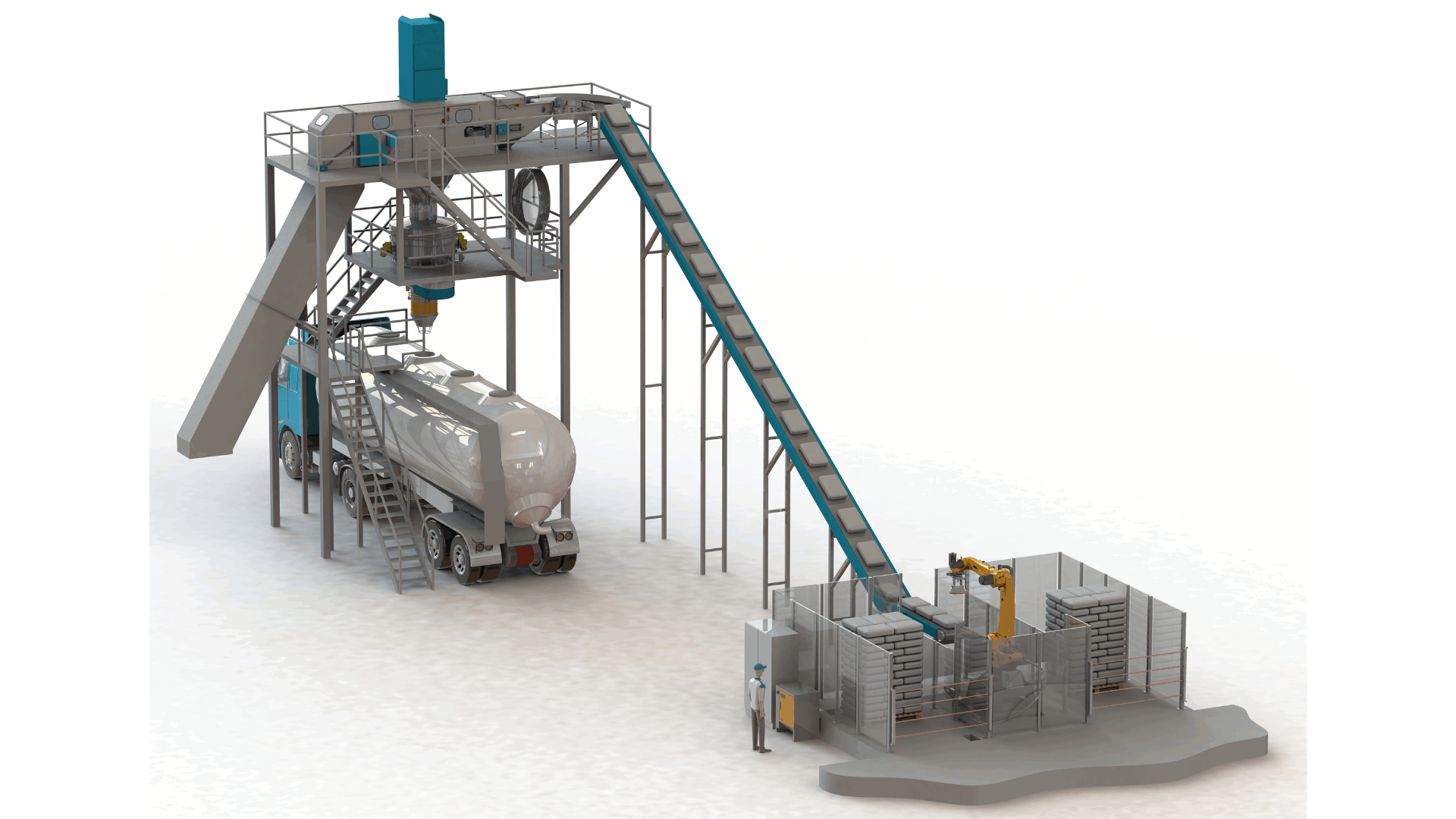

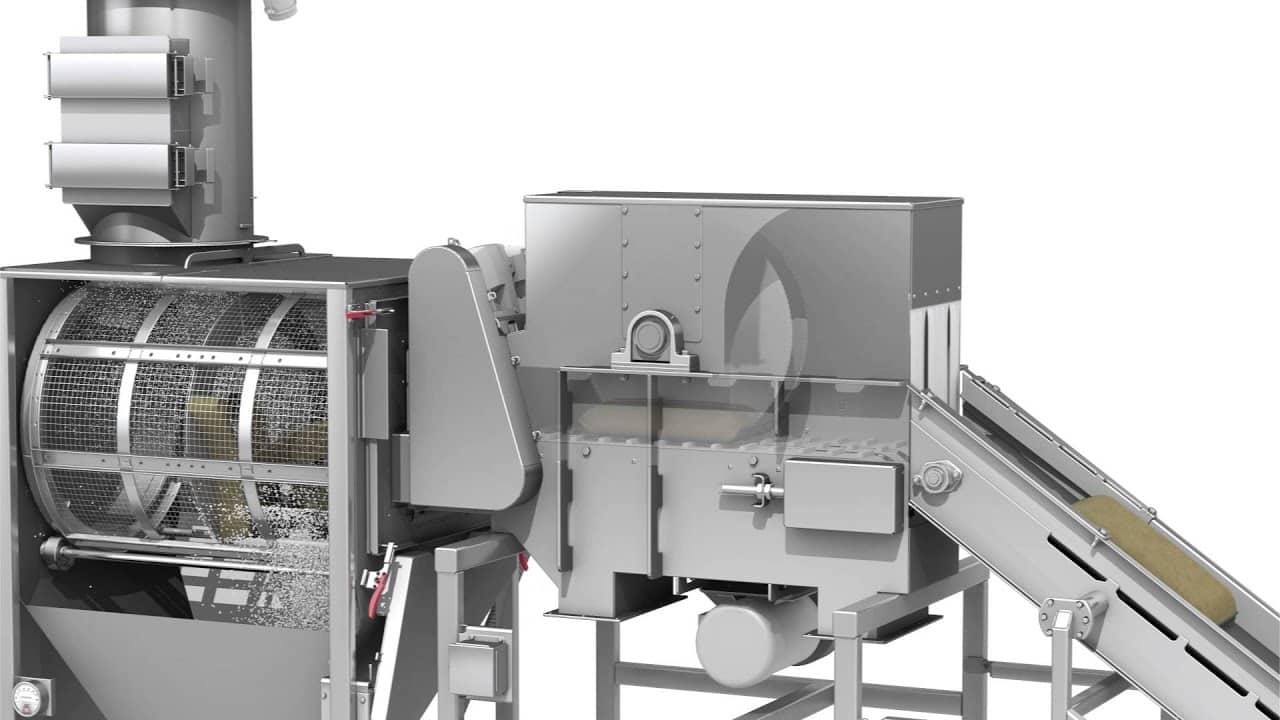

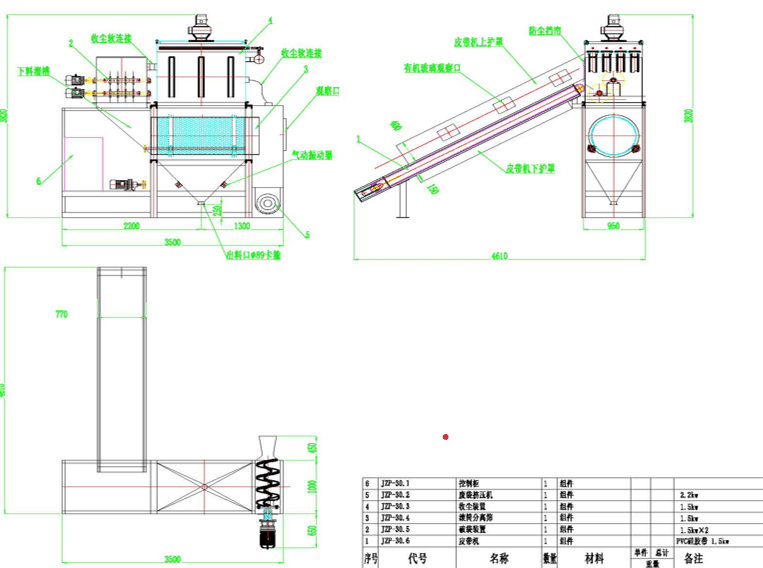

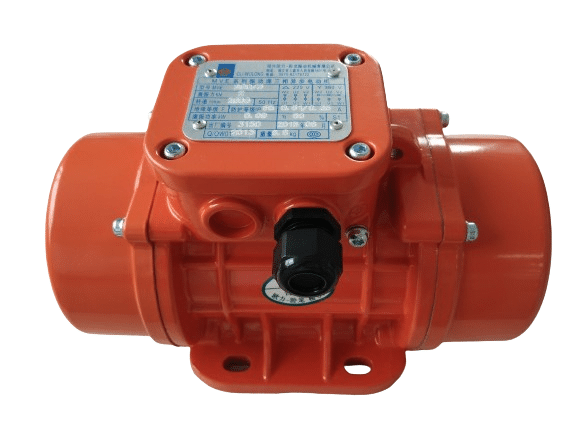

The Small Bag Automatic Unpacking Machine revolutionizes small bag handling, automating recognition, cutting, and unloading for diverse industries. Its compact design, user-friendly interface, and features like adjustable settings and dust collection ensure both efficiency and workplace safety, making it a pivotal asset in modern material handling processes.