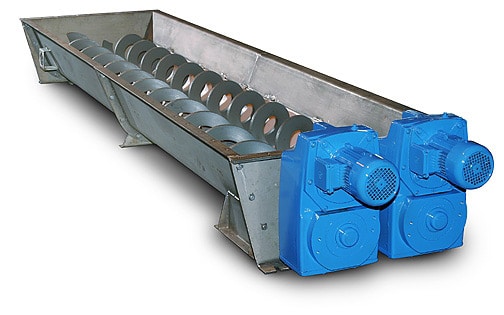

UV-LXWZ Shaftless Screw Conveyors are devices that can transport large amounts of different materials. They can handle materials that are hard to move, such as urban solid waste, sludge, food waste, and more. They are useful for many industries that deal with these kinds of materials, such as waste water treatment, sugar production, fish processing, fruit and vegetable processing, beverage production, pulp and paper, chemical industry, food industry, meat industry, and catering services.