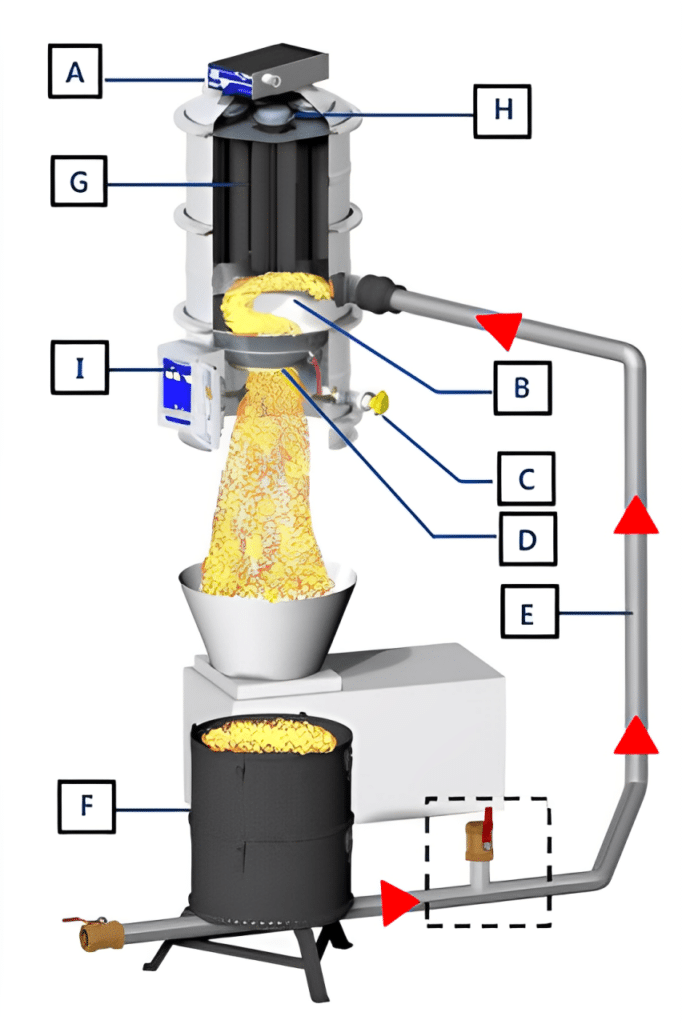

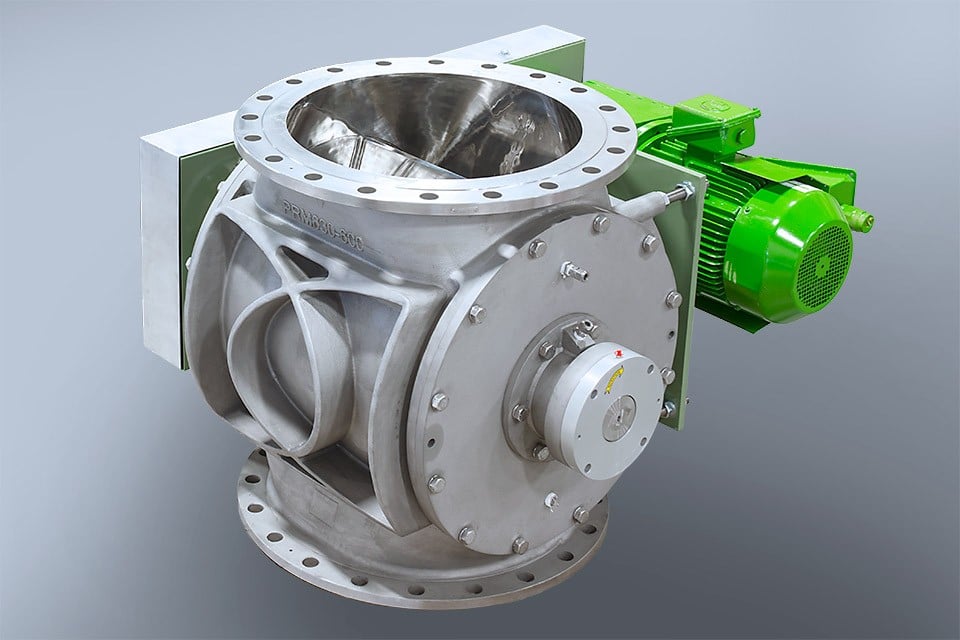

The Vacuum Feeder revolutionizes material handling through high-precision vacuum suction, seamlessly transporting powdered and granular materials with adjustable speed. Its dust-free operation ensures a clean workplace, while compatibility with centralized control systems and customizable configurations enhances efficiency in diverse industrial applications. Experience precision and adaptability with the Vacuum Feeder, setting new standards in negative pressure conveying technology.