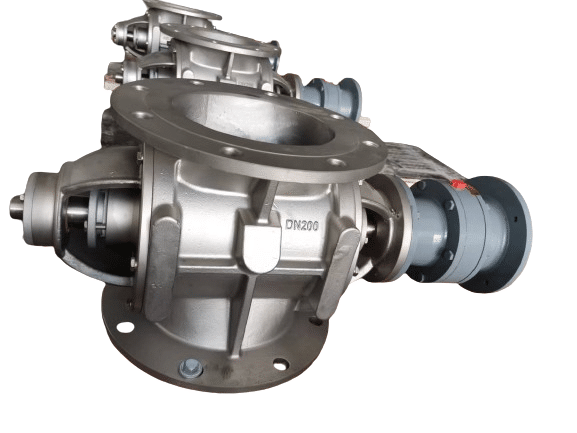

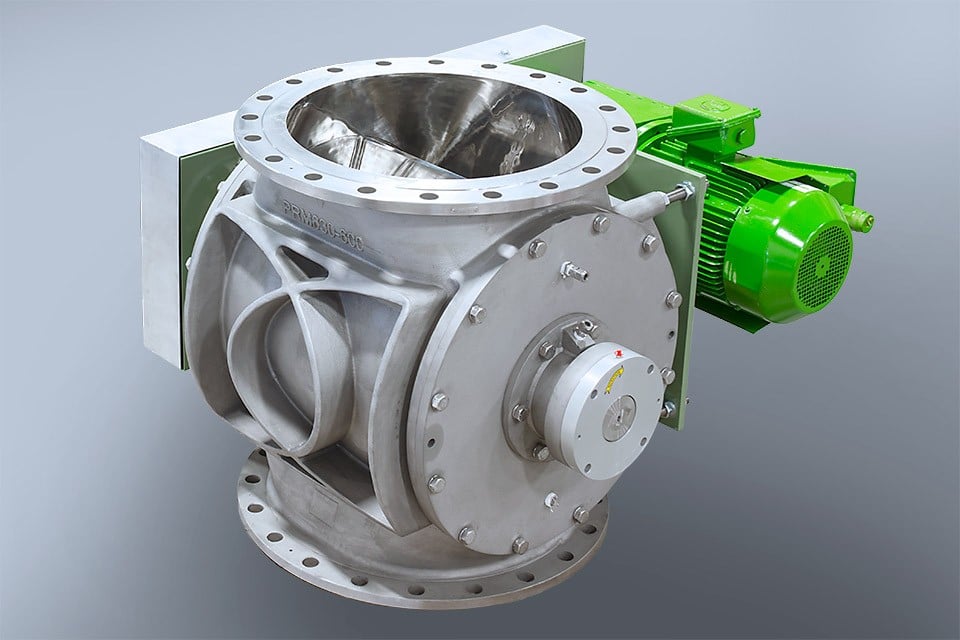

Shanghai Youwei’s Horizontal Ribbon Mixer stands as a versatile solution catering to industries spanning chemicals, pharmaceuticals, food processing, and construction. Ideal for blending powder with powder, powder with liquid, or powder with granules, this mixer ensures impeccable mixing efficiency and minimal downtime.