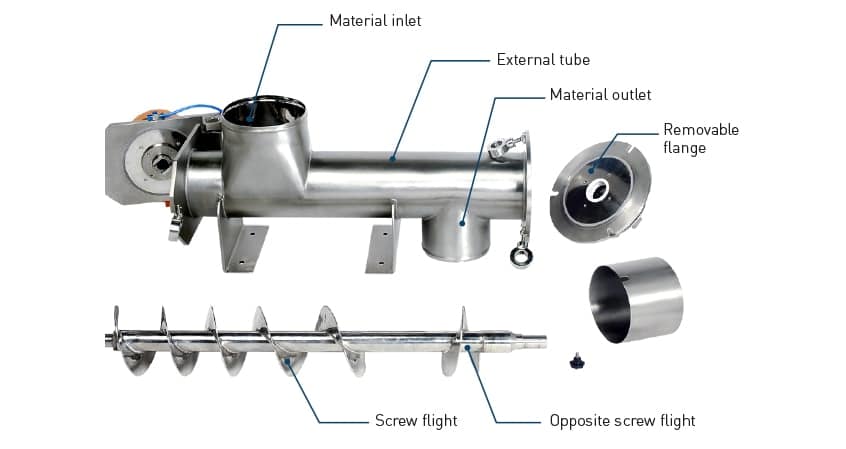

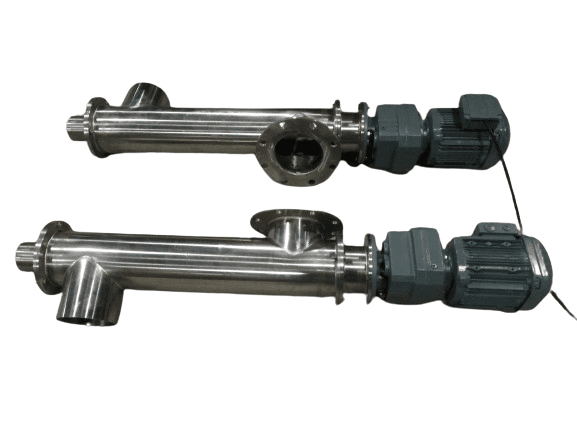

A number of standard options are available for the UV-LX Tubular Screw Conveyor and Feeder system, which is a versatile tool for handling granular or powdered materials with efficiency. Applications such as the production of concrete (managing fly ash, filler dust, silica fume), premixed building materials (dry plasters, sand, cement, additives), glass processing (including calcium carbonate, soda, sand), foundries (for sand, bentonite), and many other industries are served by a variety of conveyor and feeder models.