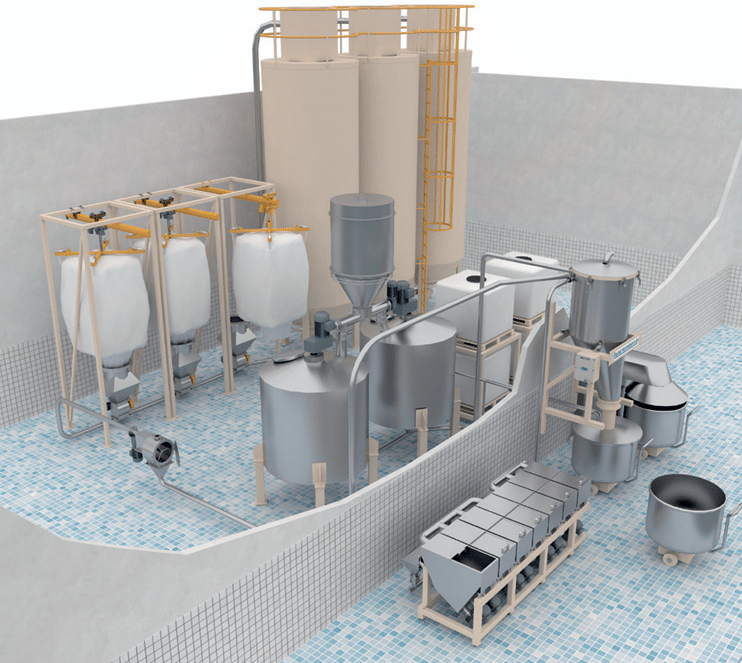

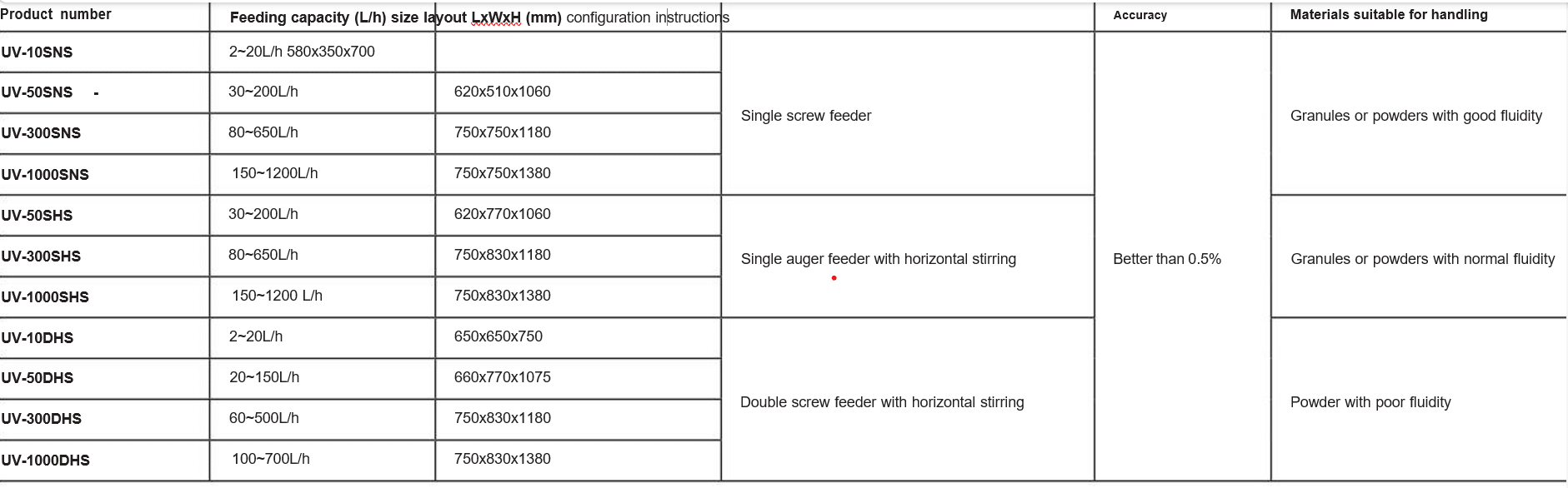

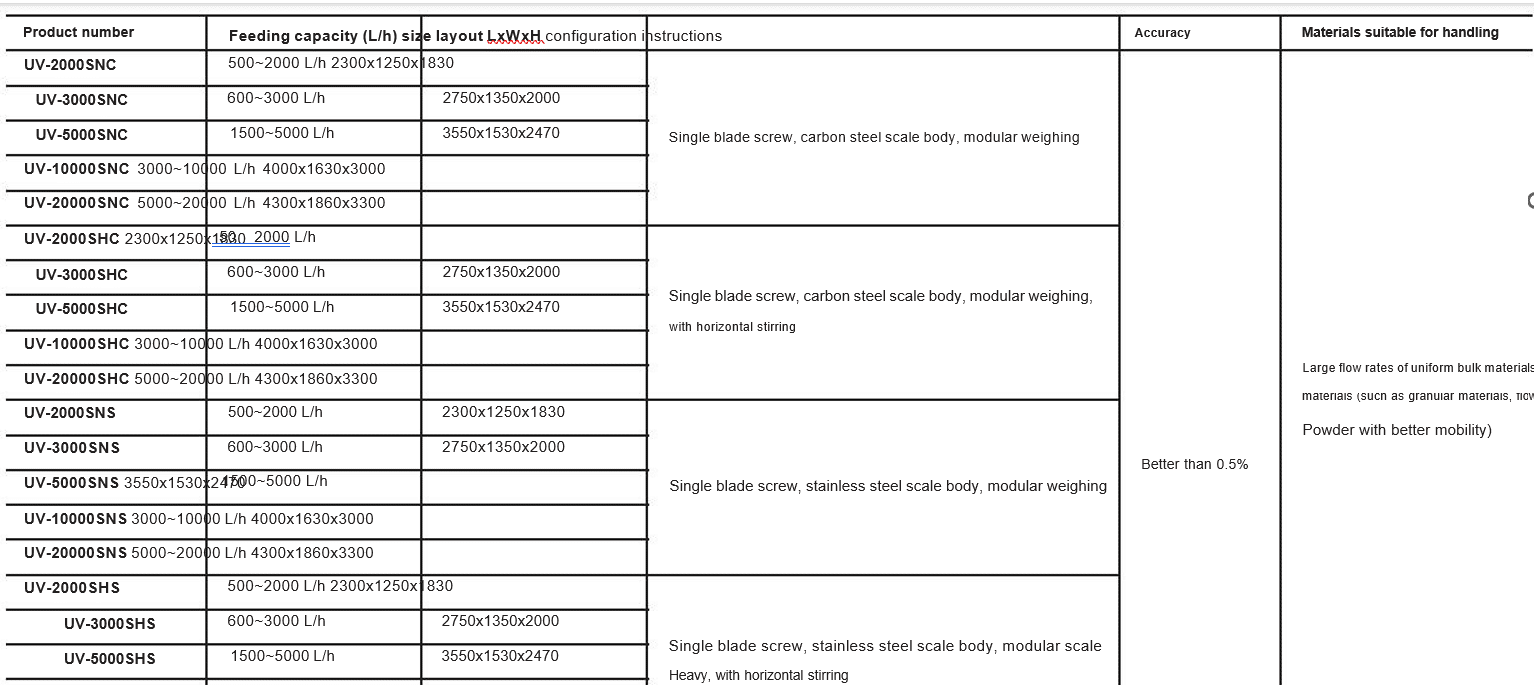

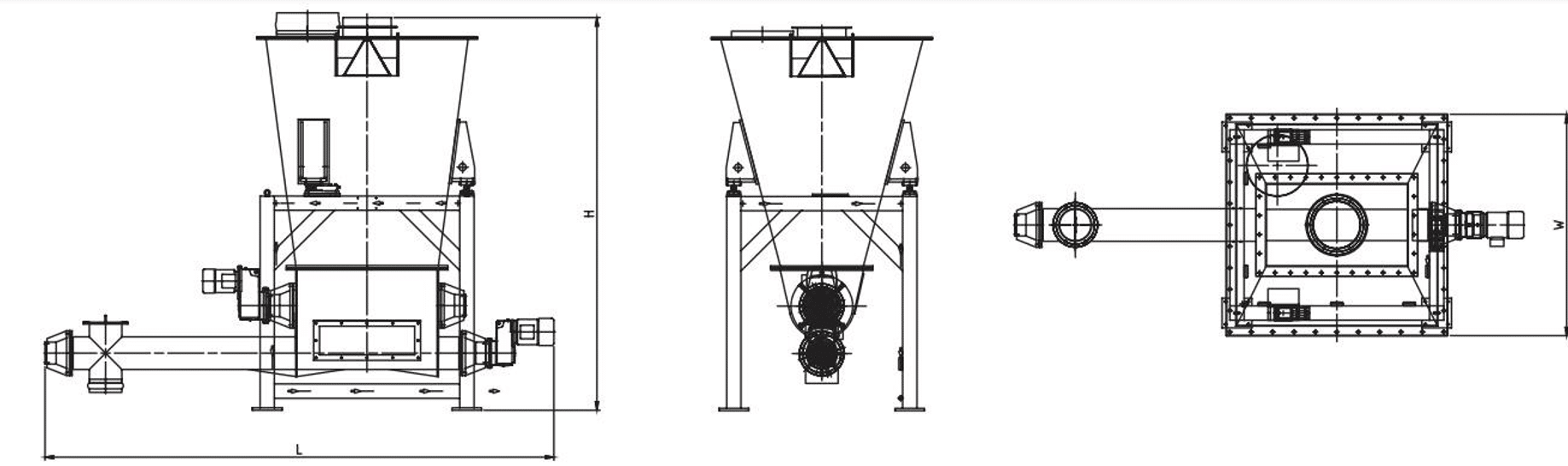

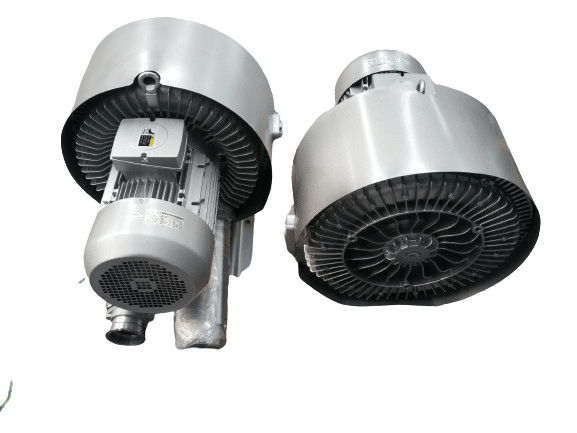

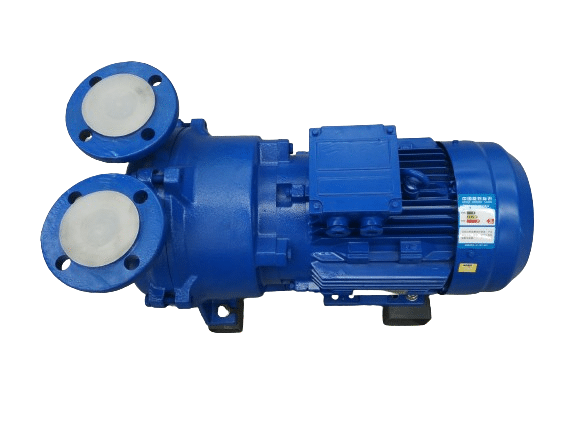

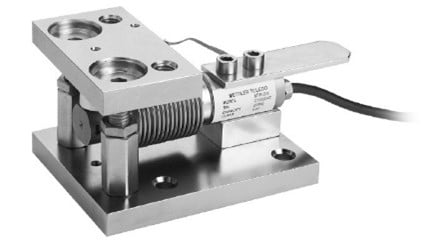

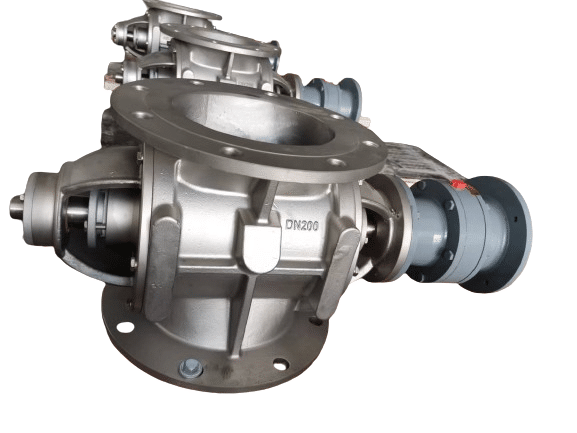

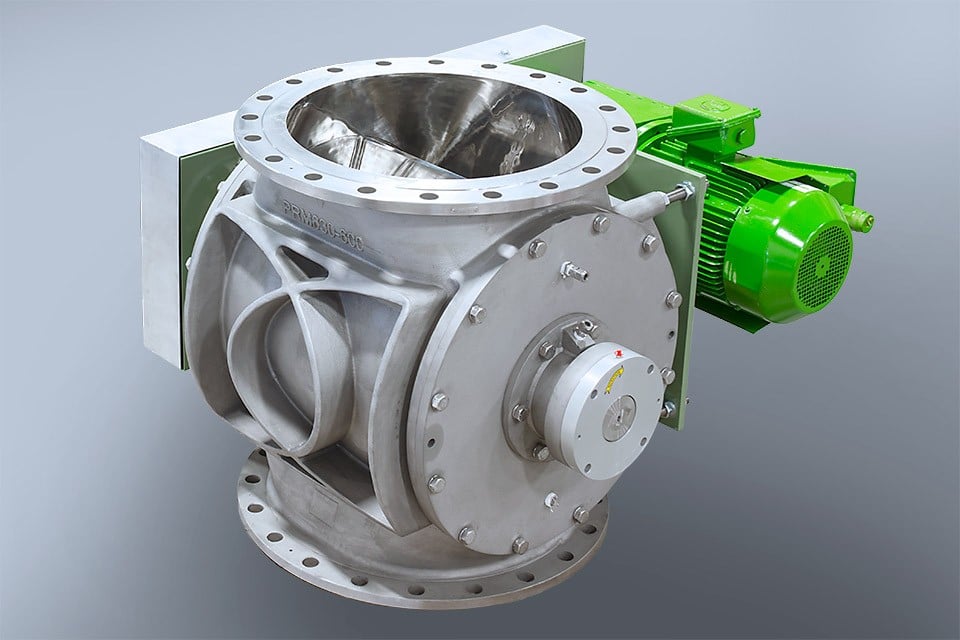

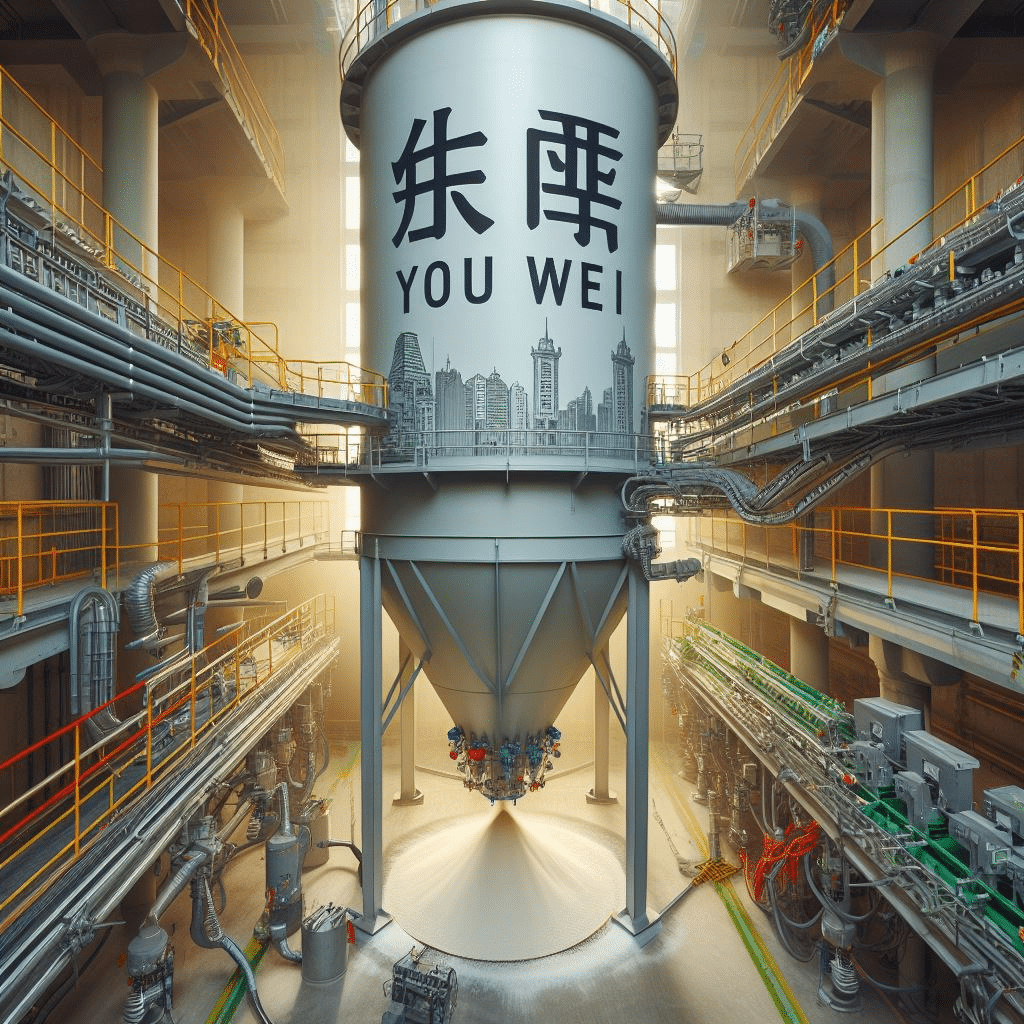

Ensuring accurate and efficient powder transfer is crucial in various industries. Shanghai Youwei offers a comprehensive range of dosing and weighing solutions specifically designed for powder conveying systems. These systems guarantee precise control over powder flow, minimizing waste and maximizing production efficiency.