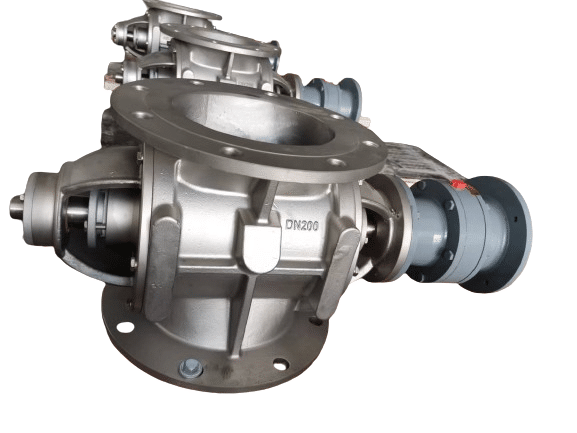

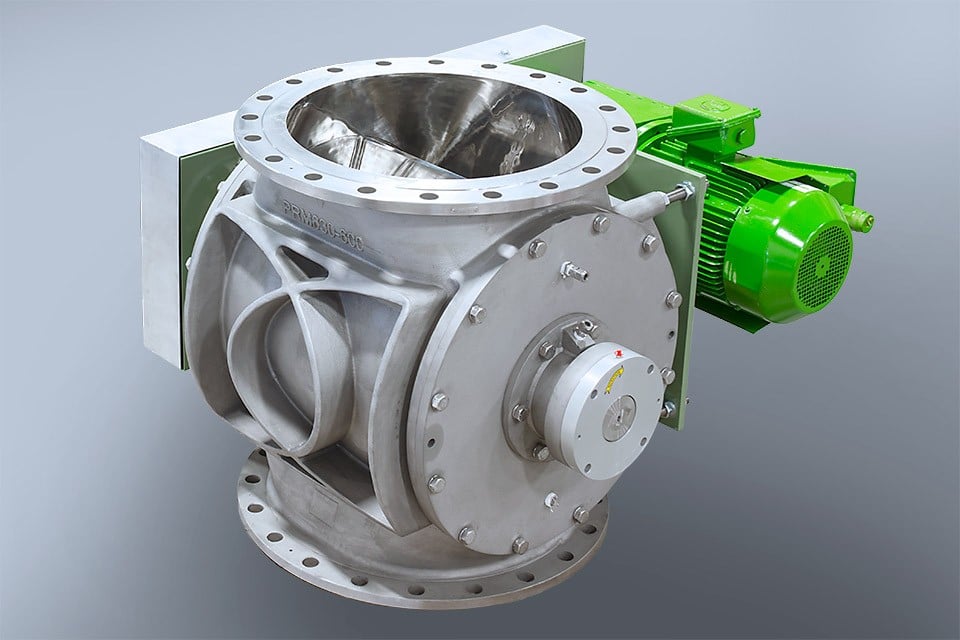

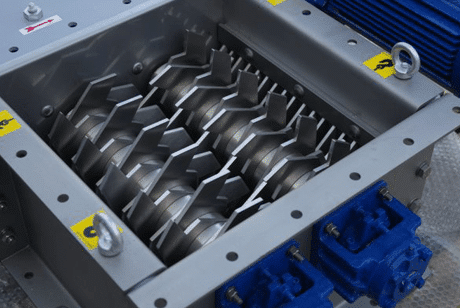

In the realm of bulk solids and powder processing, managing large, cumbersome lumps often necessitates specialized equipment. Enter the block crusher, a robust and efficient solution designed to break down oversized materials into smaller, more manageable pieces.