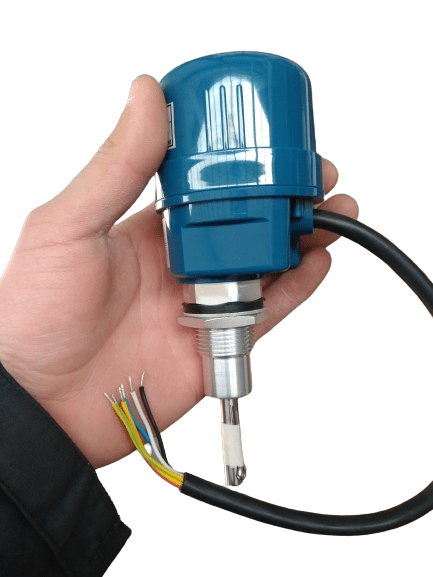

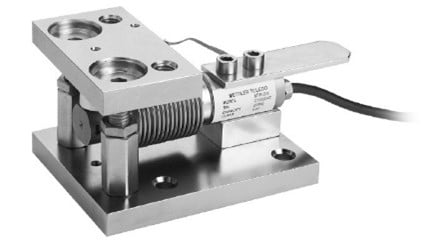

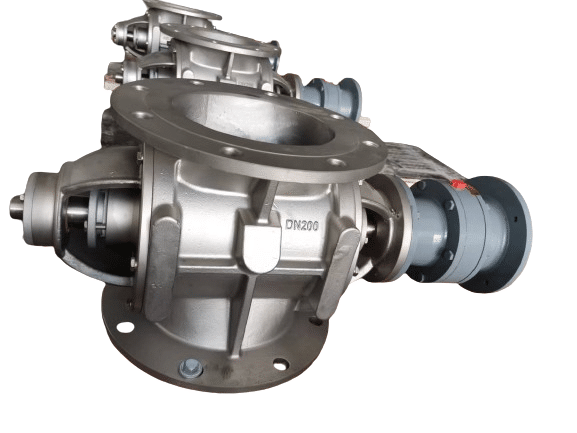

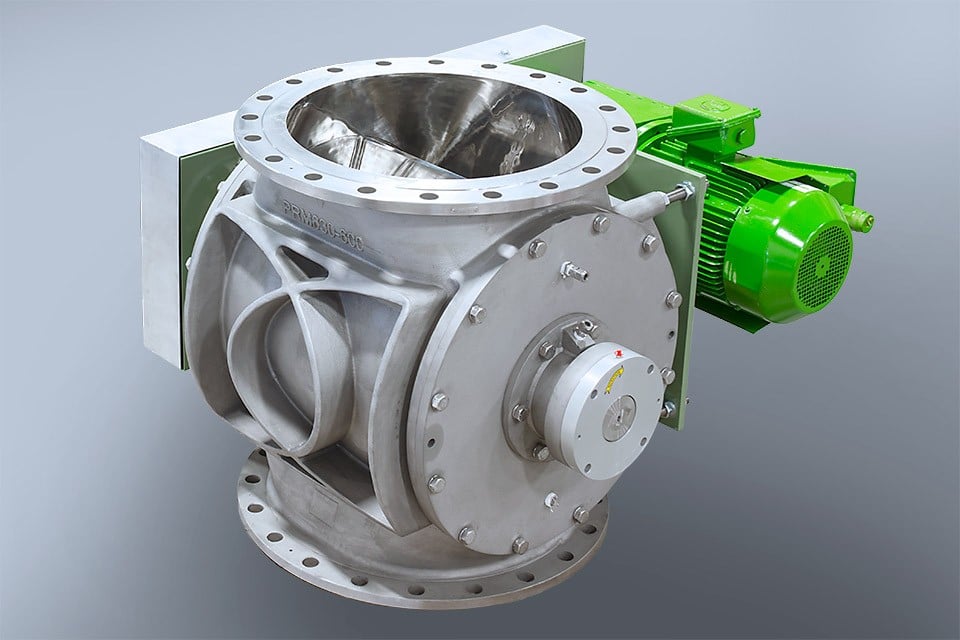

Introducing the Big Bag Packaging Machine – a game-changer in industrial manufacturing. This cutting-edge equipment ensures swift and precise packing of large quantities of materials, from powders to aggregates. With advanced weighing mechanisms and an intuitive control panel, it guarantees accuracy and adaptability across various industries. Its robust design minimizes errors, reduces waste, and significantly cuts labor costs. The modular and easy-to-maintain structure allows seamless integration into existing production lines, making it a powerhouse solution for elevating packaging efficiency and sustainability in the contemporary industrial landscape.