Introduction: When developing fluid or pneumatic conveyor systems, eductors present a viable alternative to traditional equipment like fans, blowers, and pumps. These jet pumps, also known as liquid jet pumps, operate by creating a vacuum, simplifying systems and enhancing overall efficiency. This article explores the fundamentals of eductors, their operation, types, and applications in conveying systems.

What are Eductors? Eductors, or liquid jet pumps, are tools designed for pumping air, gas, or liquid. Distinguished by their lack of moving parts, eductors rely on a motive or driving fluid to operate, making them versatile in handling various materials with minimal maintenance requirements.

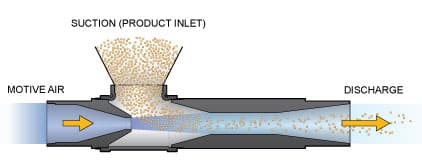

How do Eductors Work? Eductors operate based on the Venturi effect, a reduction in fluid pressure that occurs when a gas or liquid flows through a constricted pipe section. These pumps utilize pressure and an artificially created vacuum to transport air, gas, and liquids. The design involves a converging section, a constricted throat, and a diverging section to create low-pressure areas, allowing for the introduction of secondary materials.

Types of Eductors:

- Venturi Eductors: Utilize positive pressure from a blower or pump for conveying low viscosity liquids, pellets, and granular bulk solids in pneumatic conveying systems.

- Multistage Eductors: Operate in multiple stages to increase pressure and vacuum, suitable for wastewater treatment to prevent solids settling.

- Liquid Ring Eductors: Rotating positive-displacement pumps used as vacuum pumps with lower heat load and cooling water requirements.

- Peristaltic Eductors: Low-maintenance pumps using squeezing and releasing motions for handling undissolved solids and high-viscosity fluids.

Why are Eductors Used? Eductors offer several advantages in the conveying industry, including preventing product clumping, enhancing operational speed, and avoiding issues like plugged filters. They find applications in various industries such as industrial processing, wastewater treatment, chemical processing, and food production. Eductors are known for their easy installation, maintenance, and cleaning, making them a preferred choice for many conveying systems.

Incorporating Eductor Pumps: Given their numerous benefits, incorporating eductor pumps into pneumatic and liquid conveying systems is a wise decision to improve operational efficiency and reduce production costs.

Conclusion: Eductors play a crucial role in conveying systems, offering simplicity, efficiency, and versatility. Understanding their types and applications can guide the integration of these pumps into different industrial processes, leading to improved overall performance.