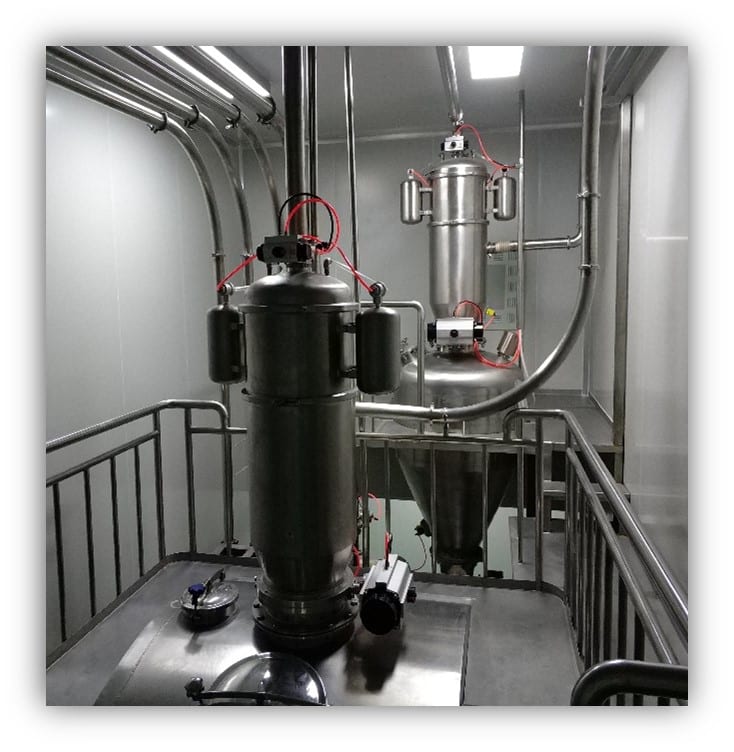

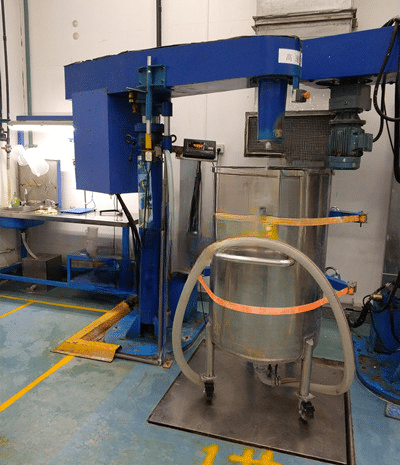

Shanghai Youwei designed and installed a vacuum conveying system for a food flavoring and fragrance manufacturer. This system efficiently transports flavorings and fragrances to the packaging machine.

Conveying Requirements:

- Destination: Packaging machine

- Conveying distance: 15 meters (including a 3-meter elevation)

- Dosing method: Variable speed and batch dosing

- Frame structure: Stainless steel, with guardrails for heights exceeding 2.5 meters

- Conveying material: Food additives (powder and granular)

Challenges:

- Precise and variable-speed dosing

- Limited ceiling height in the factory

- Potential for blockages in the conveying lines

Solutions:

- Electrical Design: Our dedicated electrical engineers crafted a complete system incorporating high-precision weighing sensors and branded variable frequency drives. This ensures user-friendly operation, enabling both accurate batch and variable-speed dosing.

- Structural Design: We customized the system dimensions based on the client’s specific site conditions, effectively overcoming the space constraints imposed by the limited ceiling height.

- Pipeline Optimization: We meticulously designed the pipeline layout, minimizing the risk of blockages and enhancing overall conveying efficiency.

System Components:

- Vacuum feeder

- Dust-free loading station

- Vacuum conveying pipeline

- Electrical control system

System Benefits:

- Precise Dosing: The system achieves dosing accuracy within 0.2%-0.5% using imported sensor technology.

- Dust-free Conveying: The entire conveying process operates within a closed loop under negative pressure, eliminating dust leaks and ensuring a clean environment.

- Cost Savings: The system’s high degree of automation reduces labor requirements. Additionally, its modular design and quick-assembly structure minimize maintenance costs.

Project Outcome:

Shanghai Youwei’s vacuum conveying system is now fully operational at the food production facility, demonstrating a conveying efficiency of 4 tons per hour. This system effectively addresses the client’s production needs.

Case Summary:

This case study showcases how Shanghai Youwei’s vacuum conveying system can overcome various challenges encountered in flavoring and fragrance conveying, including precise and variable-speed dosing, limited ceiling height, and potential blockages. This system proves to be an ideal solution for food flavoring and fragrance manufacturers.