Challenge:

Traditional methods for packaging lithium battery cathode ternary materials often suffer from drawbacks like:

- Significant dust generation: This creates safety and environmental concerns.

- Low efficiency: Manual packaging processes are slow and labor-intensive.

- High error deviations: Inaccurate packaging can lead to material waste and production disruptions.

Solution:

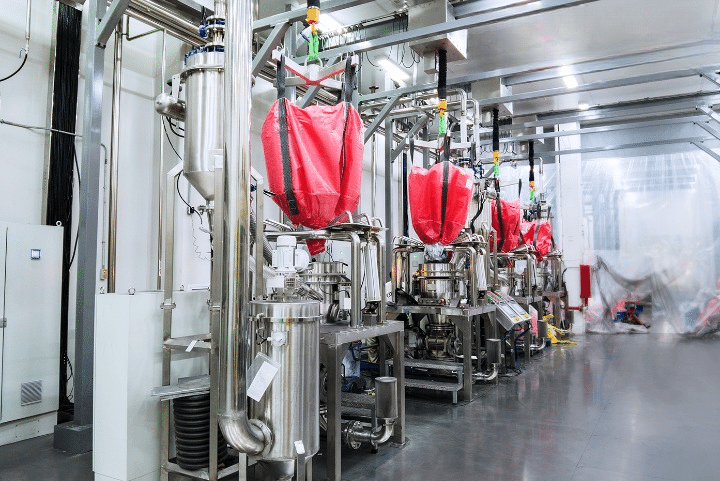

Shanghai Youwei’s automated ton bag packaging machine offers a modern solution for lithium battery companies. This innovative equipment integrates various functionalities:

- Automated weighing and measurement: Ensures precise and consistent filling of ton bags.

- Dust-free packaging: Minimizes dust generation during the process, promoting a clean and safe work environment.

- Automatic bag removal: Streamlines the packaging workflow and reduces manual labor requirements.

Key Features of the Ton Bag Packaging Machine:

- Independent development and manufacturing: Shanghai Youwei’s in-house expertise ensures quality and control over the entire development process.

- Multiple functionalities:

- Automatic feeding

- Material level alarm

- Automatic start/stop

- Automatic bag removal

- Automatic pallet loading

- Simple design and user-friendly operation:

- PLC + touch screen control system

- Convenient for production, use, and maintenance

Case Details:

Location: Zhejiang, China

Process Flow:

- Automatic feeding to the silo

- Ton bag packaging with automatic compaction

- Roller conveyor transport

Packaging Material: Lithium battery cathode ternary material powder

Additional Details:

- Sprayed packaging

- Automatic pallet loading

- China-European ton bags

- Packaging accuracy: ±0.2%

- Packaging weight: 500-1200 kg

- Packaging speed: 10-20 bags per hour

- Pneumatic bag clamping

- Mettler Toledo weighing system

- 4-point weight update

Shanghai Youwei: Your Partner in Automated Powder Handling