Challenge:

The food ingredients industry, particularly spice production, faces challenges in achieving accurate and dust-free weighing during the batching process. Traditional methods can expose workers to harmful dust and compromise product quality due to inconsistencies.

Solution:

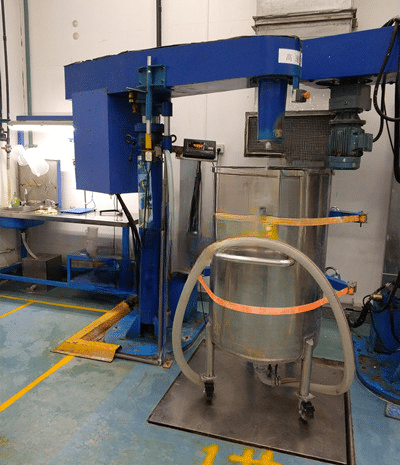

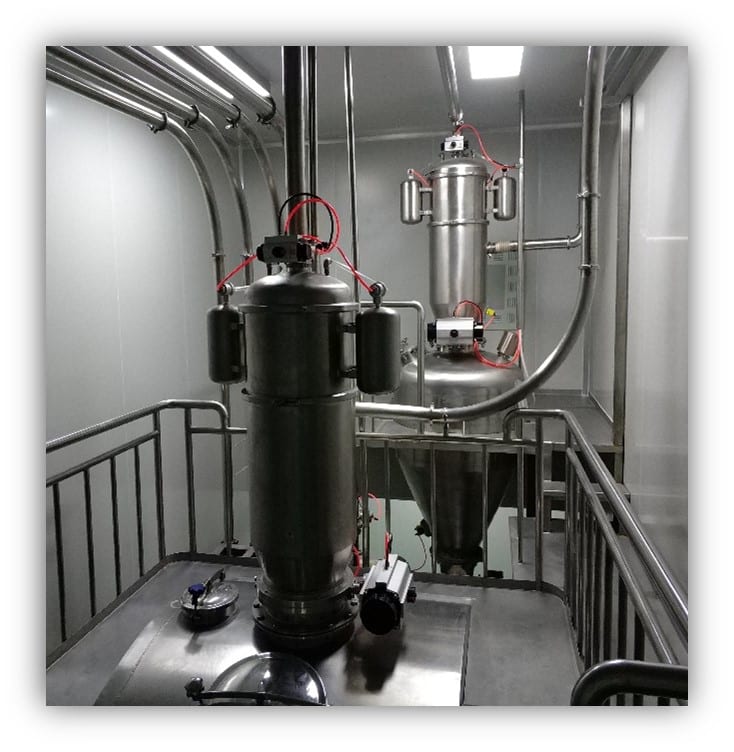

Shanghai Youwei, a leading provider of powder handling solutions, implemented a fully automatic batching system for a spice production company in Henan, China. This innovative system addressed the client’s concerns by:

- Eliminating dust exposure: The system employs a closed feeding method with a central dust collection system, ensuring a clean and safe working environment for operators.

- Ensuring accuracy: The system combines high-precision screw feeding with weighing sensors and advanced algorithms to guarantee batching accuracy within ±0.2%.

Key Features:

- Dust-free feeding: Utilizes a centralized dust collection system for a clean and healthy working environment.

- Closed-loop batching: Ensures product quality and batching accuracy by operating in a sealed environment.

- High-precision weighing: Achieves ±0.2% accuracy through a combination of screw feeding and weighing sensors.

- Efficient automation: Streamlines the batching process, reducing labor costs and increasing production efficiency.

Project Details:

- Location: Henan, China

- Ingredients: Salt, sugar, MSG, chili powder, chive powder, pepper, and other spices

- Process: Dust-free feeding, weighing, premixing, mixing, caching, packaging, and sewing

- Packing weight: 15 kg

- Material types: 13

- Measuring accuracy: 50 g

- Cache silo capacity: 1500 L

- Mixed materials capacity: 2000 L

- Feeding methods: Manual pouring and dust-free feeding

- Error-proofing: Induction door

Benefits:

- Improved product quality: Ensures consistent and accurate batching, minimizing errors and product waste.

- Enhanced safety: Eliminates dust exposure, creating a healthier work environment for employees.

- Increased efficiency: Automates the batching process, reducing labor costs and production time.

- Boosted competitiveness: Enables consistent production of high-quality spices, improving the company’s market position.

Conclusion:

This case study demonstrates Shanghai Youwei’s expertise in designing and implementing innovative solutions for the powder handling industry. Their fully automatic batching system effectively addresses the challenges of dust control and batching accuracy in spice production, leading to improved product quality, safety, and efficiency.