Challenge:

A food processing company required an efficient and hygienic solution for conveying salt, chili powder, and other food powders within their production facility. Traditional negative pressure conveying systems presented challenges like material backflow, dust leakage, and gaps during operation, impacting efficiency and creating safety concerns.

Solution:

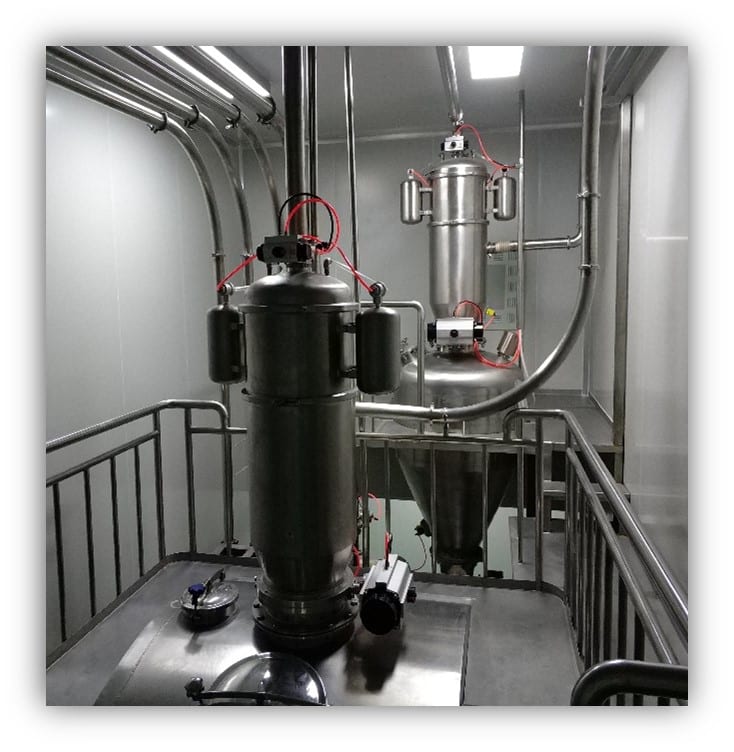

Shanghai Youwei, a renowned powder conveying and handling specialist, recommended a continuous vacuum conveying system. This innovative system addresses the limitations of traditional methods by offering:

- Continuous suction: The system operates without intervals, eliminating gaps and ensuring consistent material flow.

- Airtight operation: The closed design minimizes dust leakage and maintains a clean production environment, crucial for food safety.

- High efficiency: The continuous operation and optimized design enhance conveying efficiency, increasing production output.

Key considerations for material properties:

- Salt: Possessing good fluidity and high packing density, salt requires a reliable system to handle its demanding characteristics.

- Chili powder: Due to its irritating properties and tendency to volatilize, chili powder necessitates a high degree of vacuum to minimize powder loss and maintain air quality.

Benefits of the continuous vacuum conveying system:

- Reduced height: This feature makes it ideal for integrating into existing production lines, facilitating upgrades and modernization.

- Enhanced efficiency: The continuous operation eliminates gaps, achieving higher overall throughput compared to traditional systems.

- Optimized vacuum usage: Two feeders share a single vacuum pump, maximizing resource utilization.

- Clog-free operation: Continuous feeding prevents material backflow and clogging, ensuring smooth operation and reducing maintenance needs.

Case specifics:

- Materials: Salt, chili powder, MSG, and other food powders

- Conveying distance: 10 meters

- Material bulk density: 0.8 – 1.5 g/cm³

- Pipe bends: 4

- Instantaneous efficiency: 4-6 tons/hour

- Equipment material: SUS304 stainless steel (ensuring food-grade safety and corrosion resistance)

Design considerations:

- Limited space: The system was designed to accommodate the space constraints of the existing facility.

- High efficiency demands: The system met the required high throughput for efficient production.

- Stringent vacuum requirements: The system ensured a sufficient level of vacuum for optimal chili powder handling.

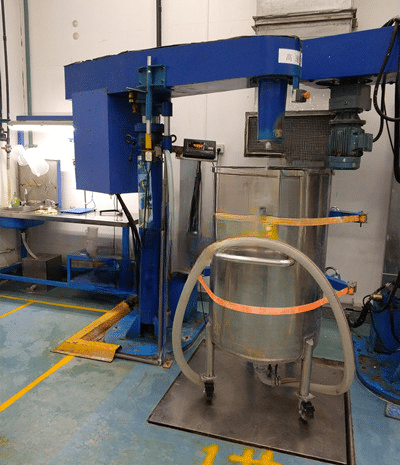

Process overview:

- Workers feed materials onto a vibrating screen.

- The continuous vacuum feeding system transports the materials to a buffer tank for temporary storage.

- The materials are then fed from the buffer tank into the mixer for further processing.

Note: For detailed system design information, contact Shanghai Youwei for a technical consultation.

Additional Services:

Shanghai Youwei offers a comprehensive range of services, including:

- Project case information: Learn about successful applications of their systems in various industries.

- Corporate sample information: Gain insights into their expertise across diverse sectors.