Challenge:

Traditional powder conveying methods often encounter challenges when dealing with ultra-long distances, high vertical heights, and fine, lightweight powders like perlite. These methods can suffer from issues like:

- Residue buildup: Material can accumulate in the system, leading to blockages and reduced efficiency.

- Backflow: Material can flow back in the opposite direction, causing contamination and production delays.

- Dust leakage: Escaped powder can create safety hazards and environmental concerns.

- High energy consumption: Constant pressurization can be energy-intensive.

Solution:

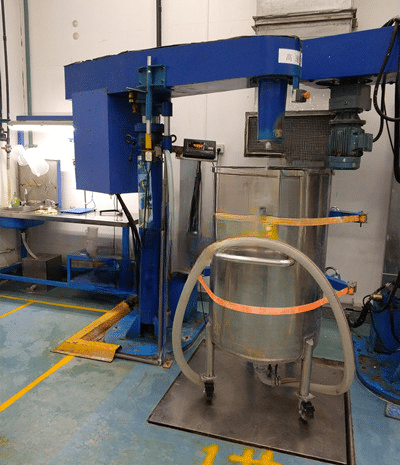

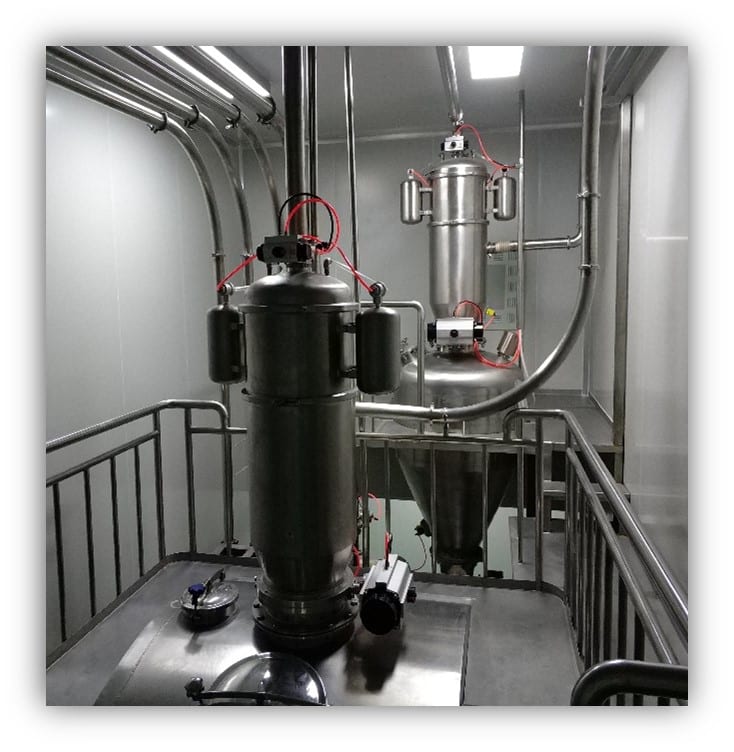

Shanghai Youwei, a leading provider of powder handling solutions, implemented a continuous vacuum feeding system for a client requiring efficient and reliable perlite powder transportation. This innovative system addressed the challenges mentioned above by utilizing the following principles:

- Continuous Negative Pressure: Material is continuously drawn through the system via a vacuum, eliminating the risk of backflow and residue buildup.

- Shared Vacuum Source: Multiple feeding points can operate efficiently without requiring additional energy for each point, maximizing resource utilization.

- Enclosed Design: The system is completely sealed, preventing dust leakage and ensuring a clean and safe operation.

Benefits:

- Long Distance & High-Rise Capability: The system effectively transported perlite powder over a 15-meter horizontal distance and a 15-meter vertical height, demonstrating its suitability for demanding applications.

- Improved Efficiency: Continuous material flow and reduced residue buildup significantly enhanced conveying efficiency compared to traditional methods.

- Reduced Energy Consumption: The shared vacuum source and efficient design minimized overall energy usage.

- Dust-Free Operation: The enclosed system prevented dust leakage, contributing to a cleaner and safer work environment.

- Easy Cleaning & Maintenance: The system design facilitated easy cleaning and maintenance, minimizing downtime and maintenance costs.

- Automated Control: The system employed PLC and touch screen control, enabling automated operation and simplifying user interaction.

Key Takeaways:

This case study showcases the effectiveness of Shanghai Youwei’s continuous vacuum feeding system in overcoming the challenges of transporting fine, lightweight powders over long distances and high elevations. The system’s efficiency, energy savings, and dust-free operation make it a valuable solution for various industries requiring reliable and safe powder handling.