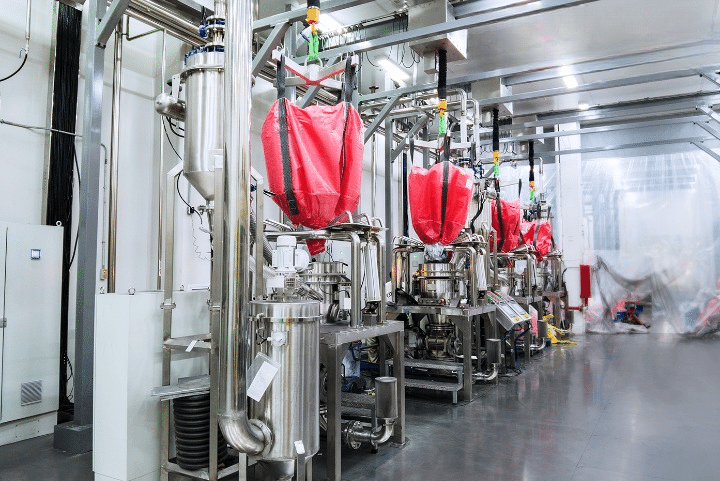

This case study explores a customized negative pressure vacuum conveying and loading system designed by Shanghai Youwei for efficient lithium iron phosphate powder (LFP) transportation in a lithium battery cathode material production facility.

Challenge:

LFP powder transportation within lithium battery cathode material production often involves multi-point retrieval from various locations and subsequent loading for further processing. Traditional methods like auger or air pump conveying, as well as manual handling, pose limitations in terms of flexibility, efficiency, and dust control.

Solution:

Shanghai Youwei’s solution is a fully customized multi-point picking and negative pressure vacuum conveying and loading system. This system offers several key advantages:

- Convenience and Efficiency:

- Multi-point retrieval: The system efficiently gathers LFP powder from multiple discharge points.

- Fast and adjustable loading: The system enables swift and adaptable loading processes without manual intervention.

- Single operator requirement: Only one worker is needed to manage the entire operation.

- Improved Safety and Cleanliness:

- Negative pressure design: The system operates under negative pressure, minimizing dust generation and ensuring a clean working environment.

- Flexibility and Cost-Effectiveness:

- Simple and adaptable pipeline layout: The system allows for easy configuration based on specific needs.

- User-friendly control system: The system features intuitive controls for convenient and visual operation.

- Low maintenance and operational costs: The system’s simple design minimizes maintenance requirements and operational expenses.

- Low failure rate: The robust design ensures system reliability.

- Customization options: The system can be customized to accommodate various conveying needs.

Project Details:

- Location: Guizhou, China

- Equipment Material: Stainless steel 304 (outer body) and tungsten carbide/Teflon (internal components)

- Conveying Process: Multi-point picking and conveying of LFP powder

- System Features:

- Backup pipeline system

- Dual redundant vacuum pump system with automatic switching

- Adjustable conveying speed

- Quantitative conveying capability

- Automatic feeding

- Weighing and batching capabilities

- Integration with leading brands like Siemens, Schneider, and MCGS

- Conveying Distance: 35 meters

- Conveying Height: 6 meters

- Material Flow: LFP powder is transferred from multiple dryers to a designated storage silo using the continuous vacuum feeding system.

Conclusion:

Shanghai Youwei’s expertise in multi-point picking, negative pressure vacuum conveying, and multi-point feeding of LFP powder makes them a strong partner for the lithium battery cathode material industry. This case study demonstrates the effectiveness of their customized system in addressing the challenges of LFP powder transportation, offering improved efficiency, safety, and cost savings.