Challenge:

Traditional food production often relies on manual handling of flour, starch, and other dry ingredients, leading to:

- Dust generation: Manual processes create dusty environments, posing health risks for workers and impacting product quality.

- Inefficiency: Manual weighing and transfer are labor-intensive, slowing down production and increasing costs.

- Inconsistent quality: Manual processes are prone to human error, leading to variations in ingredient quantities and product quality.

Solution:

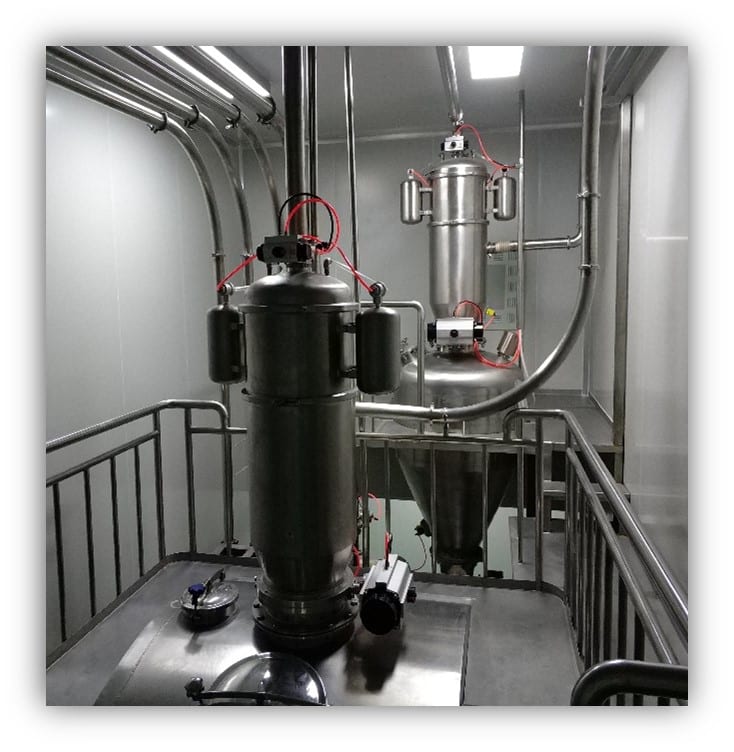

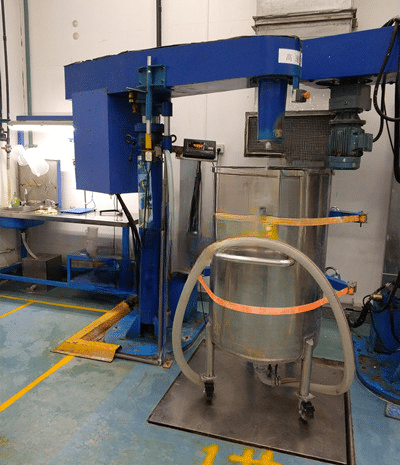

Shanghai Youwei, a leading provider of powder handling solutions, implemented a vacuum conveying and weighing system for a food production facility, addressing the stated challenges.

Key components:

- Vacuum feeder: This equipment efficiently transfers flour and starch from storage tanks to the weighing and measuring system using a negative pressure system, minimizing dust generation.

- Weighing and measuring system: This precisely measures and dispenses the required quantities of ingredients according to pre-programmed recipes, ensuring consistent product quality.

Benefits:

- Enhanced hygiene: The closed-loop vacuum system minimizes dust exposure and product contamination, promoting a cleaner and healthier work environment.

- Improved efficiency: Automated ingredient handling reduces labor requirements and production time, optimizing overall production efficiency.

- Guaranteed accuracy: Precise weighing ensures consistent ingredient ratios, leading to consistent product quality and reduced waste.

Additional features:

- User-friendly control system: The system allows for easy recipe creation and modification, facilitating production flexibility.

- Integration with existing equipment: The solution seamlessly integrates with existing production lines.

Results:

The implemented vacuum conveying and weighing system delivered significant improvements for the food production facility:

- Reduced dust exposure: The dust-free environment significantly improved worker health and safety.

- Increased production efficiency: Automated handling processes streamlined production, leading to increased output.

- Enhanced product quality: Consistent ingredient ratios ensured consistent product quality and reduced waste.

Conclusion:

This case study demonstrates the effectiveness of Shanghai Youwei’s vacuum conveying and weighing systems in optimizing the handling of flour, starch, and other dry ingredients in the food industry. Their solutions promote cleaner, more efficient, and consistent production processes, contributing to improved product quality and worker safety.