Challenge:

Graphene powder production involves processes like feeding, screening, conveying, and filling. Traditional manual operations in these complex stages can lead to:

- Dust pollution: Affecting worker health and the surrounding environment.

- Process loss: Material waste and inconsistency in product weight.

- Inefficiency: High labor costs and time-consuming procedures.

Solution:

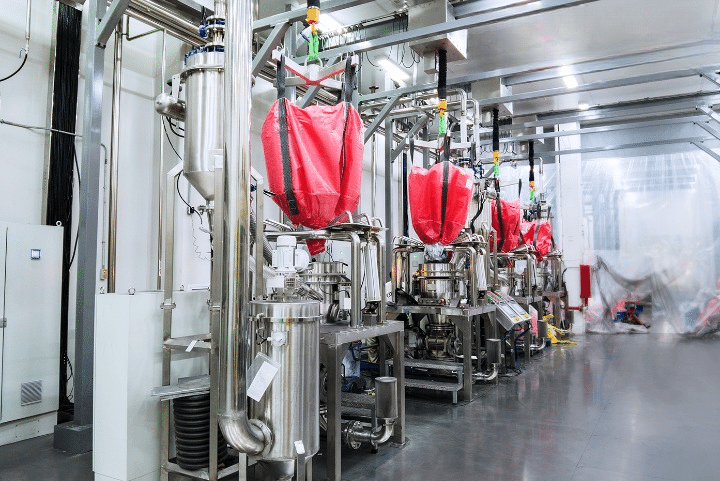

Shanghai Youwei designed and implemented a customized automatic powder handling system specifically for graphene powder. This integrated solution addresses the challenges mentioned above by incorporating:

- Dust-free feeding station: Equipped with a dust removal system that captures dust particles during material intake, ensuring a clean and safe working environment for personnel.

- Vacuum feeder: This closed-loop system efficiently conveys materials at a significantly higher rate compared to manual feeding, minimizing product loss and enhancing production speed.

- Automatic weighing and filling machine: This automated system features:

- Automatic clamping device: Ensures secure material transfer and minimizes dust leakage.

- Precise weighing and filling: Delivers consistent and accurate filling quantities, eliminating the inconsistencies associated with manual filling.

Project Outcome:

Location: Fujian, China Material: Graphene powder Filling specifications: 20kg Filling accuracy: ±20g Conveying efficiency: 2 tons per hour

Key Benefits:

- Improved product quality: Consistent and accurate filling ensures product quality and reduces material waste.

- Enhanced production efficiency: Automated processes significantly reduce labor requirements and production time.

- Dust-free operation: Protects workers’ health and the environment by eliminating dust pollution during material handling.

System Components:

- Dust-free feeding station

- Vacuum feeder

- Buffer silo

- Spiral feeder

- Vibrating screen

- Filling machine

Process Flow:

- The vacuum feeder transfers materials to the buffer silo for temporary storage.

- The spiral feeder beneath the buffer silo evenly feeds materials onto the vibrating screen for size classification.

- The screened materials are then automatically weighed and filled into designated containers by the filling machine.

Design Highlights:

- Dust-free feeding station: Incorporates an automatic pulse backflush system to extend the filter element’s lifespan.

- Vacuum feeder: Employs an innovative backflush system and unloading mechanism to ensure efficient operation and prevent dust pollution.

- Filling machine: Features a quick-fill mechanism customized for specific packaging formats and a tightly closing clamp to minimize dust leakage during filling.