This case study showcases the effective use of a vacuum feeder to ensure safe and efficient closed-loop transportation of milk powder in a food production environment.

Meeting Stringent Food Safety Requirements:

Milk powder production adheres to strict hygiene regulations to prevent contamination. Traditional conveying methods like open conveyors pose a risk of dust generation and potential product loss.

Vacuum Feeder Benefits:

- Sealed Transportation: The vacuum feeder utilizes a closed-loop system, preventing dust emission and product exposure to external contaminants. This maintains product integrity and ensures food safety.

- Gentle Material Handling: The vacuum technology gently conveys the milk powder, minimizing product degradation and preserving its delicate properties.

Project Overview:

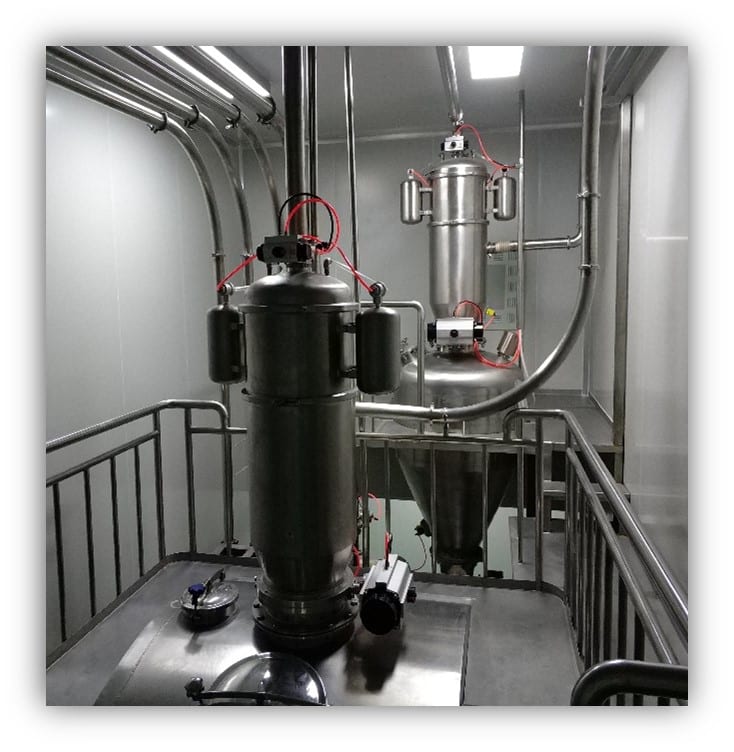

This project involved the closed-loop transportation of milk powder from a spray drying tower to a packaging machine silo. The process flow is as follows:

- Spray Drying Tower: Milk powder is produced and discharged from the tower.

- Vacuum Feeder: The milk powder is transported to a storage tank 30 meters away and 12 meters high.

- Storage Tank: The milk powder is stored in the tank.

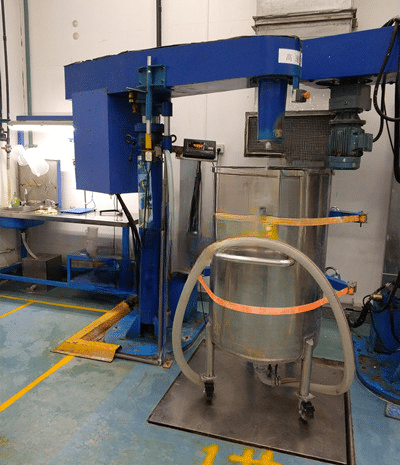

- Screw Feeder: The milk powder is precisely weighed and measured using a screw feeder based on a pre-determined formula.

- Mixer: The weighed milk powder is mixed with other ingredients.

- Vibrating Screen: The mixture is screened to ensure uniformity and remove any undesired particles.

- Vacuum Feeder: The screened milk powder is transferred to the packaging machine silo using another vacuum feeder.

- Packaging Machine Silo: The silo automatically feeds the milk powder to the packaging machine based on its signal.

Key Takeaways:

- Vacuum feeders are ideal for conveying sensitive food products like milk powder due to their closed-loop design and gentle handling.

- This case study demonstrates the effectiveness of vacuum feeders in maintaining product safety, efficiency, and automation within the food production industry.