Challenge:

The traditional manual transfer of lithium battery cathode materials, like ternary materials, lithium iron phosphate, lithium carbonate, lithium hydroxide, and iron phosphate, is inefficient, labor-intensive, and prone to human error. This can lead to production delays, inconsistencies, and safety concerns.

Solution:

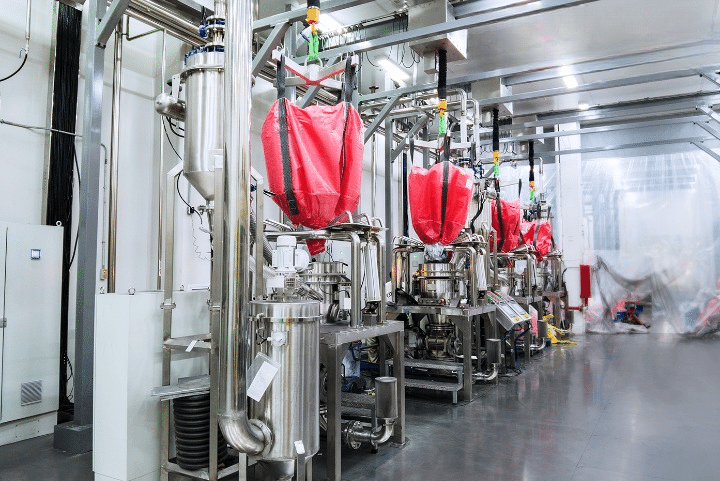

Our company implemented a vacuum feeder system to automate the transportation of these materials. The system utilizes multi-point suction and single-point suction for efficient material handling. The vacuum suction gap type continuous conveying method ensures smooth and consistent material flow.

Benefits:

- Increased Efficiency: The vacuum feeder system significantly reduces manual labor requirements, streamlining the production process and boosting overall efficiency.

- Improved Consistency: Automated material handling ensures consistent material handling, minimizing the risk of human error and product inconsistencies.

- Enhanced Safety: Eliminating manual transfer minimizes worker exposure to dust and potential hazards associated with handling these materials.

- Increased Productivity: The automated system optimizes material flow, leading to increased production capacity and output.

Project Details:

- Material Conveyed: Ternary lithium iron phosphate, lithium carbonate, lithium hydroxide, iron phosphate

- Conveying Height: 30 meters

- Conveying Distance: 40 meters

- Conveying Speed: 3000kg/h

- Control System: PLC control, connectable to DCS system

Conclusion:

By implementing the vacuum feeder system, we successfully addressed the challenges of manual material handling, achieving significant improvements in efficiency, consistency, safety, and productivity. This case study demonstrates the effectiveness of vacuum feeders in automating the transportation of ternary materials and other lithium battery cathode materials.