Shanghai Youwei successfully implemented an automatic weighing and dosing system for carbon nanotube conductive paste, a novel lithium battery conductive agent. This system automates the production process by precisely weighing and adding carbon nanotube powder and dispersant materials.

Challenges:

- Carbon nanotube powder is lightweight and prone to floating, causing dust pollution and affecting production efficiency.

- The large volume of the powder makes accurate weighing difficult.

- The varying bulk density of different batches of powder further complicates the weighing process.

Solutions:

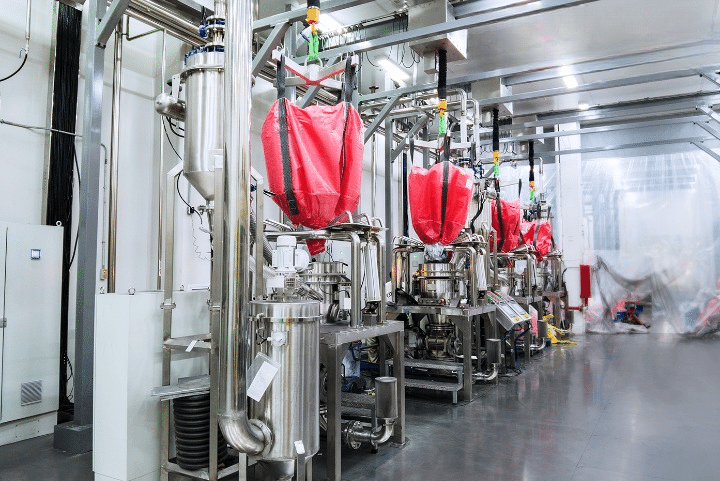

To address these challenges, Shanghai Youwei designed a customized solution:

- Fully enclosed conveying and feeding: The system utilizes a closed-loop design to minimize dust dispersion, ensuring a clean and safe working environment.

- Precise weighing and dosing: The system incorporates high-precision weighing sensors from Mettler Toledo, achieving accurate and consistent material addition.

- Flexible configuration: The system supports a wide weighing range (3-50kg) and can be customized to accommodate different production requirements.

System Benefits:

- Improved production efficiency: The automated system eliminates manual weighing and reduces labor costs.

- Enhanced product quality: Precise material addition ensures consistent product quality and performance.

- Reduced environmental impact: The enclosed system minimizes dust emissions, contributing to a cleaner production environment.

System Components:

- Material bin

- Conveyor

- Buffer hopper

- Weighing and dosing unit

- PLC control system

- Mettler Toledo weighing sensor

- Intelligent level sensor

Project Details:

- Client: Leading manufacturer of carbon nanotube conductive paste

- Weighing materials: Carbon nanotube powder and dispersant

- Weighing range: 3-50kg (customizable)

- Process: Powder conveying, feeding, buffering, weighing, dosing, and conveying to mixing equipment

- Control system: PLC + touchscreen

- Sensors: Mettler Toledo weighing sensor, intelligent level sensor

Conclusion:

Shanghai Youwei’s automatic weighing and dosing system successfully addresses the challenges of carbon nanotube conductive paste production. This system demonstrates our expertise in designing and implementing customized solutions for complex material handling applications.