Challenge: Traditional food powder companies face challenges in maintaining production efficiency, reducing labor costs, and ensuring a clean and safe work environment. Manual feeding of powders like corn flour, chili powder, and fried chicken powder can be time-consuming, labor-intensive, and generate dust, impacting product quality and worker health.

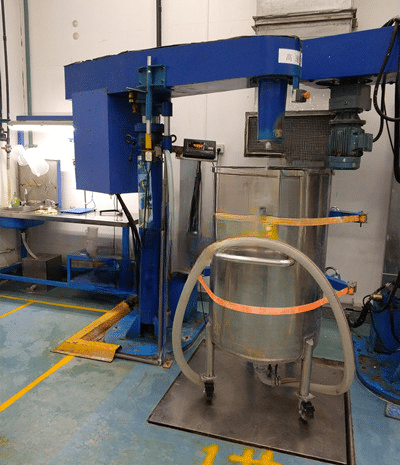

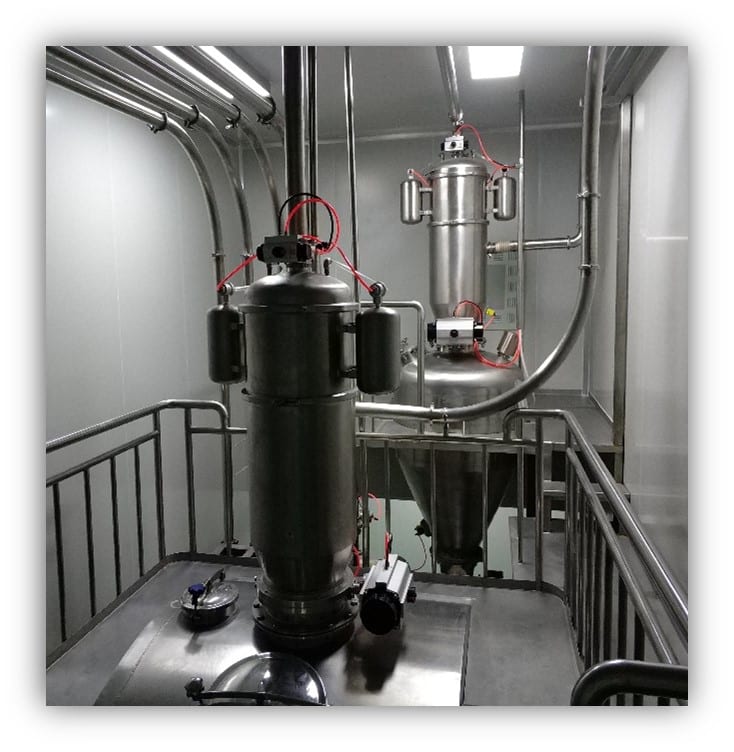

Solution: Shanghai Youwei implemented a vacuum feeding system to automate the feeding process for a food powder production facility in Shanghai. This case study highlights the system’s benefits:

- Customized Design: Youwei’s engineers designed the system to fit the specific needs of the facility, considering factors like building height limitations, material type, and feeding distance (13 meters) and height (3 meters).

- Automated Feeding: The system seamlessly integrates with existing processes like vibrating screening and mixing. Materials are automatically transferred to a buffer tank and then fed to the mixer as needed, ensuring consistent and accurate dosing.

- Reduced Labor Costs: Automation eliminates the need for manual feeding, reducing labor costs and allowing workers to focus on higher-value tasks.

- Improved Efficiency: The automated system significantly increases production efficiency by streamlining the feeding process.

- Enhanced Safety: The vacuum technology minimizes dust generation, promoting a cleaner and safer work environment for employees.

- Maintained Product Quality: The system ensures gentle handling of food powders, preventing product degradation and preserving quality.

Results:

- The system successfully reduced labor costs and improved production efficiency.

- The automated feeding process minimized dust pollution, contributing to a cleaner and safer work environment.

- The solution received positive feedback from the customer, demonstrating its effectiveness in addressing the challenges of traditional food powder production.

Key Takeaways:

This case study demonstrates the advantages of vacuum feeding technology for automating food powder production. By implementing such systems, companies can achieve:

- Reduced labor costs

- Improved production efficiency

- Enhanced safety and cleanliness

- Maintained product quality