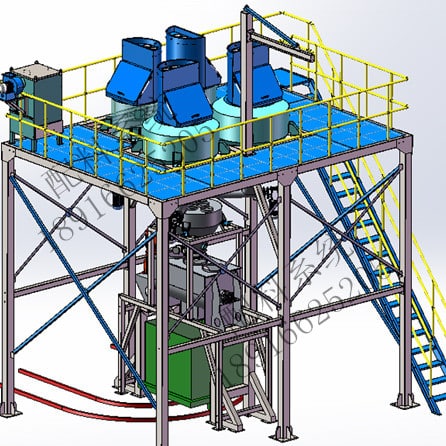

Revolutionizing Battery Production with Efficiency and Precision

The system is designed for the precise batching and mixing of carbon battery raw materials such as acetylene black, zinc oxide, and manganese dioxide. It automates the process of unpacking, weighing, and mixing these powders to create a consistent and high-quality product

Overview: The manufacturing of carbon batteries demands accuracy and efficiency in every step. Our system simplifies the complex process into three key stages:

System Operation

- Unpacking and Feeding: The system begins with the unpacking of raw materials. For smaller quantities (10-25kg), an automatic unpacking machine is used, ensuring minimal manual handling and reducing exposure to dust. Larger quantities (300-1000kg) are managed with a ton bag unpacking machine, designed to handle bulk materials efficiently and safely.

- Weighing and Feeding: Following unpacking, materials are transported to a weighing system. This involves screw feeding mechanisms that precisely measure the weight of each component according to the formula requirements. The accuracy of this step is crucial for maintaining the quality and consistency of the final product.

- Mixing: The final step is the thorough mixing of the weighed materials. This process ensures a homogenous blend of the raw materials, which is essential for the performance and reliability of the carbon batteries.

Key Points

- Dust-Free Operation: One of the system’s primary advantages is its ability to operate without generating dust. This is crucial not only for maintaining a clean work environment but also for preventing contamination of the materials, which could compromise battery quality.

- Precision: Accurate weighing and thorough mixing are emphasized to ensure that the final product meets stringent quality standards. The system’s automation ensures consistent precision in every batch.

- Automation and Efficiency: High automation levels reduce the need for manual intervention, lowering labor costs and minimizing human error. The system’s design for stable, long-term operation demonstrates its reliability and efficiency in a production setting.

Technological Advancements

The system incorporates several technological advancements to achieve its goals:

- Automated Unpacking Machines: These machines are designed to handle materials of varying quantities efficiently, minimizing manual labor and exposure to materials.

- Screw Feeding and Weighing Systems: These components ensure precise measurement of materials, crucial for maintaining the quality of the final product.

- Mixing Technology: Advanced mixing technology ensures a homogenous blend of materials, critical for the performance of the carbon batteries.

Benefits

- Reduced Labor Intensity: The system’s high degree of automation significantly reduces the labor intensity associated with the handling and processing of raw materials.

- Minimal Dust Pollution: By employing specialized unpacking and feeding equipment, the system minimizes dust pollution, creating a safer and cleaner working environment.

- Stable and Reliable: Demonstrated stable performance in long-term production settings underscores the system’s reliability and effectiveness in meeting production demands