Shanghai Youwei successfully implemented a vacuum conveying system for transporting cobalt tetroxide powder, a critical raw material in lithium battery production. This case study highlights the benefits of automated and dust-free conveying for improved efficiency and worker safety.

Challenges:

- Dust pollution: Traditional manual transportation methods for cobalt tetroxide powder generate significant dust, leading to a hazardous working environment and potential product contamination.

- Inefficiency: Manual loading slows down production and increases labor costs.

Solution:

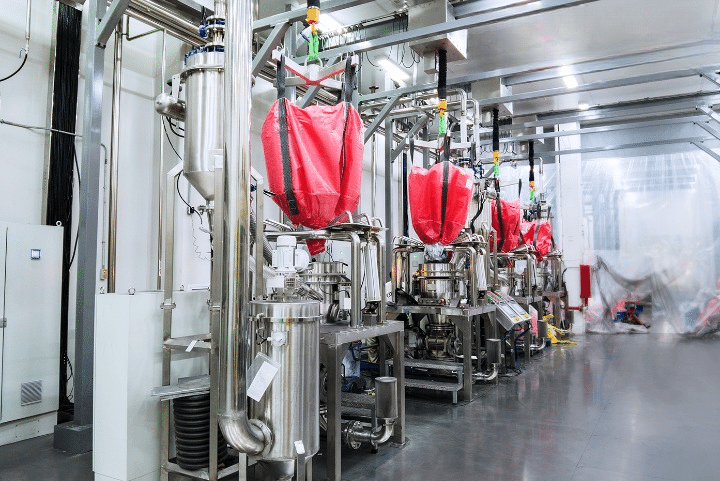

Shanghai Youwei designed and installed a customized vacuum conveying system featuring:

- Automatic loading: The system utilizes a vacuum feeder for automated and dust-free loading of cobalt tetroxide powder.

- Clean and efficient conveying: The system operates under negative pressure, effectively capturing dust particles and ensuring clean material transfer.

- PLC automation control: The system features PLC control for efficient operation, allowing both remote and local control.

Project Results:

- Improved worker safety: The automated and dust-free solution minimizes dust exposure and enhances the overall work environment.

- Enhanced production efficiency: Automated loading and efficient conveying significantly increase production speed.

- Reduced labor costs: Automation reduces reliance on manual labor, lowering operational costs.

- Clean production site: The vacuum technology ensures a clean and dust-free production environment.

Project Details:

- Conveying material: Cobalt tetroxide powder

- Conveying height: 8 meters

- Conveying distance: 5 meters

- Control method: PLC automation control

Conclusion:

This case study demonstrates how Shanghai Youwei’s vacuum conveying system effectively addresses the challenges of traditional cobalt tetroxide powder handling. The system delivers numerous benefits, including improved worker safety, enhanced production efficiency, reduced labor costs, and a clean working environment. This solution is ideal for companies seeking to optimize their lithium battery production